Digital Transformation in Manufacturing: 3D Printing

When leaders decide to take on digital transformation initiatives at their companies, they have several goals in mind. But perhaps one of the most apparent and critical gains they are looking to make is around time-to-market. After all, time is our most precious commodity. Nowadays and into the future, getting solutions to market faster than your competition is a substantial advantage. The digital transformation in manufacturing is a clear advantage toward quicker time-to-market.

In traditional manufacturing, you create and move fixtures and tooling through a set of discrete processes. This means smaller batch sizes and production runs. Between each run, tools must be changed and the next batch needs to be set up. These transitions hamper productivity, increase costs and slow product development and launch cycles. Embarking on a digital journey can change that.

3D Printing is Part of the Digital Transformation in Manufacturing

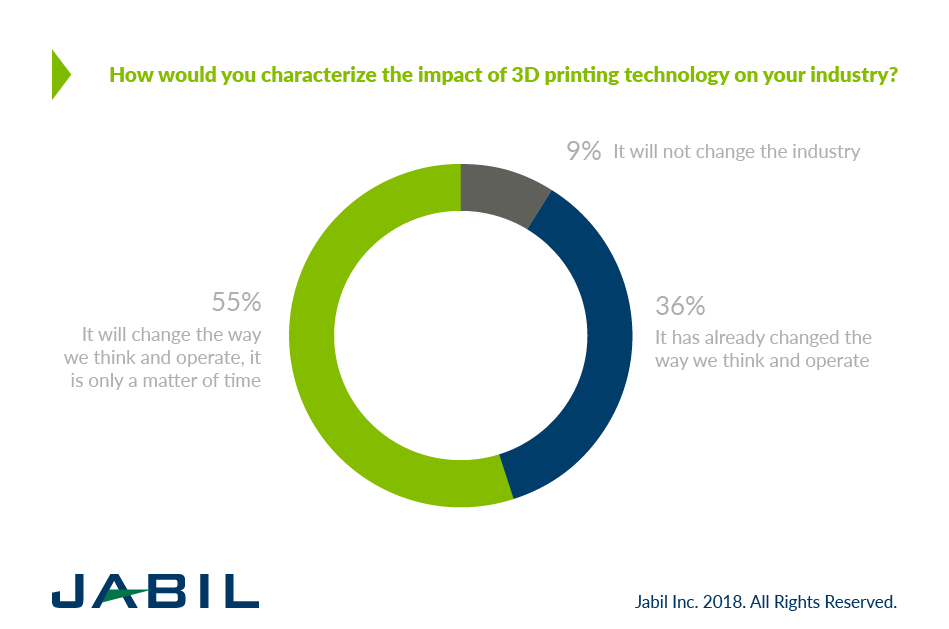

In a recent 3D Printing Trends Survey sponsored by Jabil, 36 percent of respondents stated that additive manufacturing has changed the way they think and operate. Another 55 percent shared that the practice will change how they approach manufacturing very soon.

Additive manufacturing doesn't require cumbersome tool or mold revisions, eliminating the time and cost associated with production change-over. It's a simple process:

- Send the digital Computer-Aided Design (CAD) file to the printer

- Print the part(s)

- Clear the build unit

- Repeat

- Perform appropriate post-processing steps

New products often require many design iterations and prototypes before they are ready for market. Additive Manufacturing significantly compresses this design cycle. In the time it takes to make one iteration using traditional practices, 19 iterations can be completed with 3D printing. That is a significant speed gain over traditional manufacturing methods.

In addition, we have seen additive manufacturing breakeven points climb from 5,000 units to up to 40,000 units, as we recently realized in our partnership with HP, using 3D printers to produce 3D printer parts. This technology is ready for real manufacturing applications beyond prototyping.

But beyond the cost-savings and productivity gains, additive manufacturing gives brands an extra edge over the competition. Additive manufacturing enables a digital transformation.

Empowering Your Digital Transformation with Additive Manufacturing

Since additive manufacturing utilizes CAD files, virtual teams across the globe can collaborate to create a shared design community. Instead of reviewing physical prototypes over video calls or having to take a flight over to another country, collaborators can print their own prototypes and communicate virtually, in real-time. They can work together in a more rapid fashion than what's available with traditional practices. That saves more than just the cost of a round-trip flight.

The same concept can be applied to your employees in the plants. Someone in the U.S. can design a fixture and determine the best design practice. In less than 24 hours, another employee in Mexico can take that best practice and implement it into their work without having to reinvent the wheel. In addition to unparalleled speed, this enables the standardization of your work globally. It's the digital transformation in manufacturing at work.

Subscribe to the Jabil Blog

Sign up for weekly updates on the latest trends, research and insight in tech, IoT and the supply chain.

What is Distributed Manufacturing?

Distributed manufacturing is the process of decentralizing production to manufacture the final product closer to the end-consumer. With no tools and no custom parts like traditional processes, additive manufacturing enables this practice with a digitally-threaded core. It allows a more collaborative, transparent and efficient supply chain. All of this, of course, would not be possible without a strong IT infrastructure.

When coupled with the intelligent digital supply chain, additive manufacturing can magnify your distributed manufacturing practices and overall success. With real-time insights into the health of your supply chain, you can analyze historical data and utilize predictive analytics to proactively respond to changing market conditions. Production rates may also be modified based on location, delivering a competitive edge.

Through our work with additive manufacturing, we effectively utilize distributed manufacturing. Our research and development team in Silicon Valley works seamlessly with local production groups as well as with those at a smart factory in Singapore, where final parts are manufactured. Digital files are exchanged for prototyping and final production parts, streamlining the whole manufacturing process.

Digital Transformation in Manufacturing: Reaching Your Goals with 3D Printing

In Jabil's 2018 Digital Transformation Trends Survey, we asked respondents about their top business goals around digital transformation initiatives in the coming years. Some of the most important ones included:

- Gaining better business insights with improved visibility and analytics

- Enhancing margins through operational efficiencies

- Supporting new business models

- Enabling new markets or revenue streams with new product offerings

- Defending and strengthening competitive position

It's worth noting that while your organization may be aiming for all or a combination of these goals, additive manufacturing can help you get there!

Eighty-one percent of survey respondents shared their intent to transform their factories and other facilities to better leverage cutting edge innovations. It's living proof that factories will be a key frontier in digital transformation - in this case, bolstered through the enablement of distributed manufacturing through 3D printing. How will you face the digital transformation in manufacturing?

Jabil's 2018 Digital Transformation Report

Click the download button to get Jabil's report, based on a survey of more than 200 business and technology stakeholders.