The Strategic Difference Between Supply Chain Management and Procurement

The Covid-19 pandemic brought supply chain management from a behind-the-scenes function to a critical, strategic focus across industries. Where these activities once quietly supported operational efficiency, they are now vital to the competitive strategies for many of the world’s leading companies.

As supply chains grow more complex, companies are constantly improving their methods to source materials efficiently, on time, and within budget. At the core of this effort is supply chain management, which encompasses procurement as a critical function for sourcing materials, managing supplier relationships, and supporting overall supply chain efficiency.

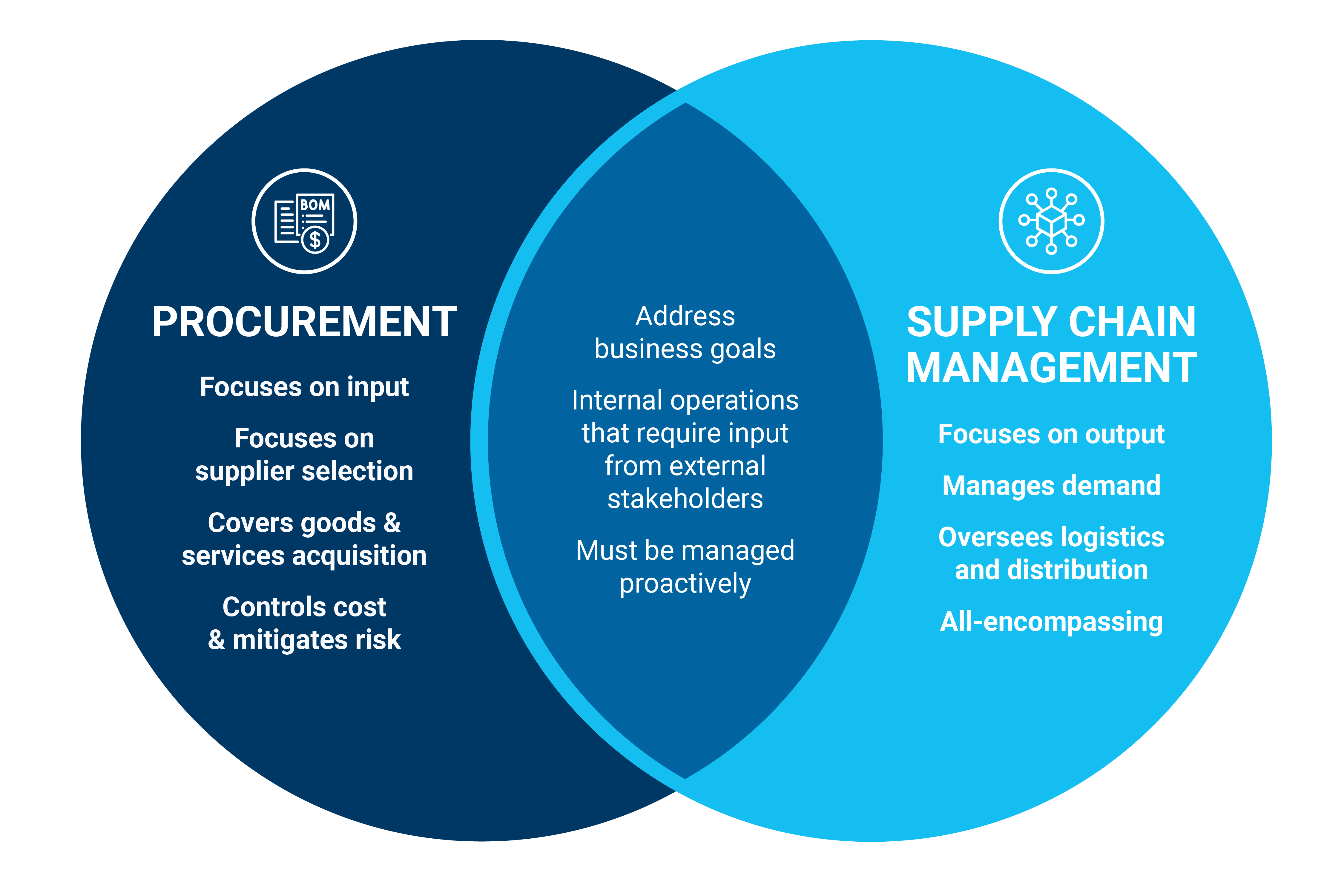

Understanding the difference between supply chain management and procurement is key to streamlining operations, reducing costs, and remaining agile. While academics often define procurement as a function within the broader supply chain, many organizations, including Jabil, structure them as parallel functions to encourage productive tension and drive efficiency. By recognizing their distinct roles and optimizing both, businesses can create a more resilient, high-performing supply chain that supports long-term success.

Jabil’s Procurement and Supply Chain Services team helps businesses optimize these functions by providing real-world insights gained from over 50 years of practitioner experience.

Defining Procurement

Procurement is the process of identifying, acquiring, and managing the goods and services necessary for an organization’s operations. It involves strategic sourcing, vendor selection, negotiation, and supplier relationship management.

Core Functions of Procurement:

Needs Analysis: Determining what materials or services are required to support business objectives.

Supplier Selection and Management: Identifying and evaluating suppliers based on their reliability, capacity, cost-effectiveness, and ability to meet quality standards.

Negotiation and Contract Management: Securing favorable terms and conditions, handling contract renewals, and managing supplier obligations.

Cost Control & Optimization: Keeping procurement costs in check by negotiating favorable terms and leveraging economies of scale.

Risk Mitigation: Preparing for potential supply disruptions, both operational and financial and managing relationships to avoid delays.

Through Jabil’s Procurement Managed Services, our team helps organizations identify reliable suppliers, negotiate competitive contracts, and improve overall supply chain performance. By working closely with finance, quality, and operations teams, procurement professionals ensure businesses secure high-quality materials and services at the best value.

Defining Supply Chain Management (SCM)

Supply chain management is the holistic oversight of the flow of goods and services from supplier to end-user. SCM covers the entire lifecycle of a product — from sourcing raw materials, through production, to logistics, and finally delivery. SCM teams are responsible for creating a seamless process that minimizes costs, reduces lead times, and ensures customer satisfaction.

Core Functions of Supply Chain Management:

Demand Management – the process of receiving a customer forecast, analyzing and aligning on the optimal data to load into MRP. (S&OP)

Production Planning: Coordinating with manufacturing teams to ensure that raw materials are transformed efficiently into finished products.

Inventory Management: Ensuring optimal stock levels to meet demand while avoiding excess and obsolete inventory.

Logistics and Distribution: Overseeing the transportation and warehousing of goods to deliver them on time and in good condition.

Customer Satisfaction: Ensuring that the final delivery meets customer expectations in terms of timing, quality, and reliability.

With so many moving parts, many businesses turn to outsourcing partners like Jabil to improve efficiency and gain better visibility into their networks. By refining processes and strengthening their networks, companies can navigate supply chain challenges more effectively and keep things running seamlessly.

Key Differences Between Supply Chain Management and Procurement

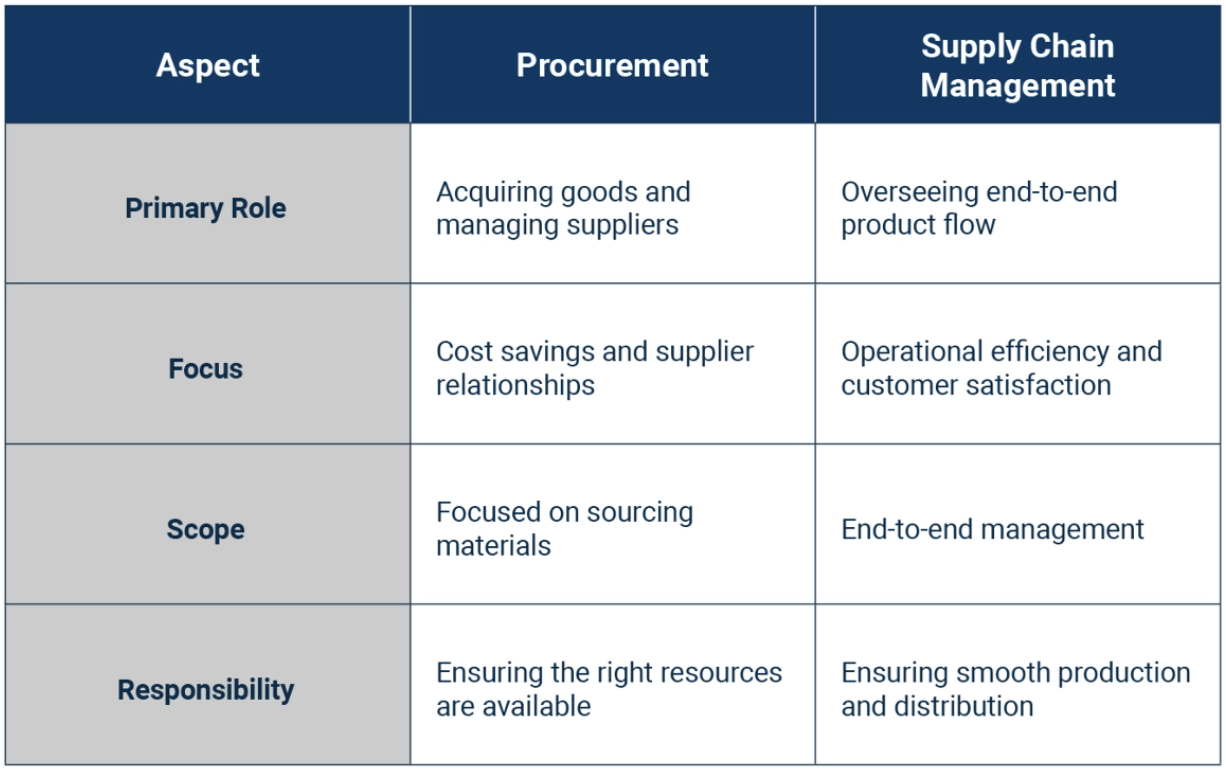

While procurement zeroes in on finding the best quality materials at the best price, managing contracts, and building strong supplier relationships, it’s only the beginning of the journey. Supply chain management takes these sourced materials and oversees their smooth and efficient flow through production, warehousing, and delivery to the end customer.

Together, these functions form a dynamic duo, each playing a crucial role in keeping businesses agile, cost-effective, and responsive to market demands.

%2015.28.13.png)

How Procurement and Supply Chain Management Work Together

Although these functions can often be distinct, procurement and supply chain management share similar goals and often intersect in key areas:

Cost Efficiency: Both procurement and SCM teams contribute to cost competitiveness. While procurement minimizes purchase costs, SCM optimizes logistics and production, also exploring alternative options to reduce the total cost of goods sold.

Risk Management: Effective procurement mitigates risks like supplier unreliability, while SCM addresses production or logistical risks.

Quality Control: Procurement focuses on quality in sourcing materials, while SCM ensures quality standards are upheld throughout production and distribution.

Sustainability Initiatives: In many organizations, both functions collaborate on initiatives to reduce waste, capacity constraints, enhance eco-friendly sourcing, and streamline logistics.

Working together, procurement and SCM create a balanced strategy that drives both cost-effectiveness and seamless delivery.

Aligning Procurement and Supply Chain Management Strategies

When procurement and supply chain management work in sync, organizations can improve operational efficiencies, strengthen supplier relationships, and deliver better customer satisfaction. This integration enables companies to proactively manage industry shifts, reducing delays and minimizing costs.

For example, recent global supply chain disruptions highlighted the need for procurement and SCM to collaborate closely. Companies with well-coordinated procurement and supply chains were able to secure alternate suppliers and adjust production schedules, enabling them to adapt smoothly to changing market demands.

Jabil’s 50+ years of procurement and supply chain practitioner expertise has helped organizations strengthen the integration of these critical functions, creating resilient supply chains that adapt to an evolving marketplace.

Understanding the Difference Between Supply Chain Management and Procurement

The distinction between supply chain management and procurement is fundamental for organizations aiming to optimize efficiency, quality, and cost leadership. Procurement secures the resources and services needed to fulfill production, while SCM oversees the transformation and delivery of those resources into market-ready products.

As industries continue to evolve, the importance of aligning procurement and SCM will only grow, making it imperative for businesses to invest in talent, technology, and best practices that support collaboration between these critical functions.