Procurement Process Improvement:

Strategies for Streamlined Success

Procurement is the crucial link between your suppliers and your business operations. It’s the all-too-important safety net that makes sure you have the right materials and resources to keep things running smoothly.

As global supply chains continue to settle in a post-pandemic era, procurement has become more than just a back-office function. It has become a way for businesses to stay ahead, adapt to market changes, and grab new opportunities.

But let’s face it. Outdated systems, manual tasks, and poor supplier communication can grind normal operations to a halt, skewering your bottom line.

When you understand and invest in your procurement strategies, you’re not just protecting your bottom line; you’re paving the way for future growth. This is where an expert perspective makes all the difference. Outsourcing partners like Jabil helps businesses assess their procurement strategies, uncover inefficiencies, and implement process improvements that lead to measurable cost savings and operational success.

Let’s dive into several proven strategies that can help you optimize your procurement processes and future-proof your supply chain.

Understanding Your Current Procurement Process

Before making improvements, procurement leaders should first ensure they have accurate, real-time data to guide decision-making. Data serves as the foundation for procurement operations, driving insights into performance, inefficiencies, and opportunities for optimization. Once the data is in place, mapping out workflows helps teams understand process gaps and determine where to focus their efforts.

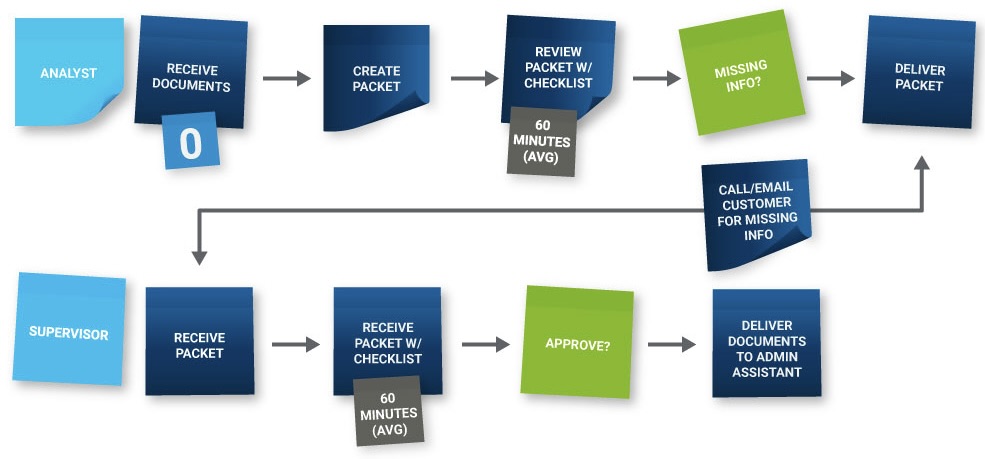

Process Mapping

Process mapping is like creating a blueprint for your procurement workflow. It visually outlines each step, from identifying suppliers to payment processing, helping your team see task connections, ownership, and potential areas for delays. Different map types serve various needs: flowcharts show inputs and decisions, swimlane diagrams highlight team handoffs, and high-level maps provide a macro view.

Performance Metrics

While process maps show where issues exist, performance metrics measure how well your procurement operates. Tracking Key Performance Indicators (KPIs) is essential for understanding how well your procurement system is working. Common KPIs include:

- On-Time Delivery Rate: Measures supplier reliability

- Cost Savings Achieved: Tracks budgetary impact

- Procurement Cycle Time: Evaluates the time taken for purchase approvals

- Supplier Performance Rating: Assesses overall supplier quality, responsiveness, and compliance with contractual agreements

By analyzing these metrics, businesses can identify trends and opportunities for improvement.

Leveraging Technology for Procurement Process Improvements

Understanding your current workflows is just the beginning. To truly enhance procurement efficiency, embracing digital transformation is essential. With 74% of global supply chain leaders increasing investments in technology and innovation, staying competitive means adopting modern tools. These technologies streamline processes, boost accuracy, and offer real-time visibility. The right digital strategies reduce manual effort, minimize errors, and enable faster, data-driven decisions, keeping your business agile and efficient.

Automation

In 2025, an impressive 96% of companies are using AI-powered tools to automate procurement processes. Automating tasks like invoice processing, inventory tracking, and purchase order approvals allows your team to focus on strategic initiatives. This minimizes human error and speeds up workflows. Leveraging a procurement technology can help businesses adopt and optimize procurement platforms, providing real-time data, greater transparency, and faster, more informed decision-making.

Procurement Software

E-procurement platforms and supplier portals automate manual tasks like creating purchase orders and communicating with vendors. These tools consolidate procurement activities into a single interface, reducing administrative burden and improving overall workflow efficiency.

For example, supplier portals streamline communication and collaboration by allowing partners to review and respond to POs and maintain supplier profiles, certifications, and compliance documents. Source-to-Pay technologies like Coupa increase spend visibility, automate workflows, and optimize spend management, enabling cost savings, compliance, and efficiency across the entire procurement lifecycle. Leveraging a procurement consulting provider can help you quickly adopt and optimize your e-procurement tools.

Data Analytics

Procurement technology makes it easier to spot spending patterns and find ways to save. For instance, if you’re placing a lot of small orders with the same supplier, bundling them into larger, less frequent purchases can cut costs and simplify logistics. Additionally, repetitive purchases may be better managed through a hosted or punchout catalog, freeing up procurement teams to focus on more strategic tasks.

Supplier Relationship

Management (SRM)

Building strong supplier relationships is key to creating a smooth, efficient procurement process. These relationships should be focused on fostering trust, collaboration, and mutual growth – not just transactions.

Strategic Sourcing

Selecting the right suppliers is about more than just finding the lowest cost—it’s about ensuring resilience, reliability, and long-term alignment with business goals. A well-balanced supplier network helps mitigate risks such as decommits, material shortages, and price fluctuations. Tapping into Jabil’s team of procurement practitioners can help businesses identify and vet suppliers, explore diversification strategies, and negotiate stronger terms to enhance buying power. By focusing on strategic sourcing, companies can create a stable, high-performing supply base that supports scalability and innovation. Tap into Jabil’s team of procurement practitioners can help you select the right suppliers for your needs, explore diversification strategies, and strengthen your buying power.

Supplier Performance Management

An optimized procurement process relies on supplier accountability and continuous improvement. Establishing clear performance metrics—such as defect rates, on-time delivery, and responsiveness—enables companies to monitor supplier effectiveness and address potential issues before they escalate. Regular performance reviews, open communication, and data-driven insights create a culture of transparency and mutual growth. Strong supplier management not only ensures quality and consistency but also drives efficiency gains throughout the supply chain.

Supplier Collaboration

True procurement optimization goes beyond managing transactions—it requires deep collaboration with suppliers to drive efficiency and unlock new opportunities. By sharing demand forecasts, production schedules, and market intelligence, businesses can help suppliers plan proactively, minimize lead times, and improve responsiveness. Joint problem-solving and innovation initiatives foster stronger partnerships, leading to cost savings, process improvements, and even new product development. Companies that invest in supplier collaboration position themselves for greater agility and resilience in an evolving marketplace.

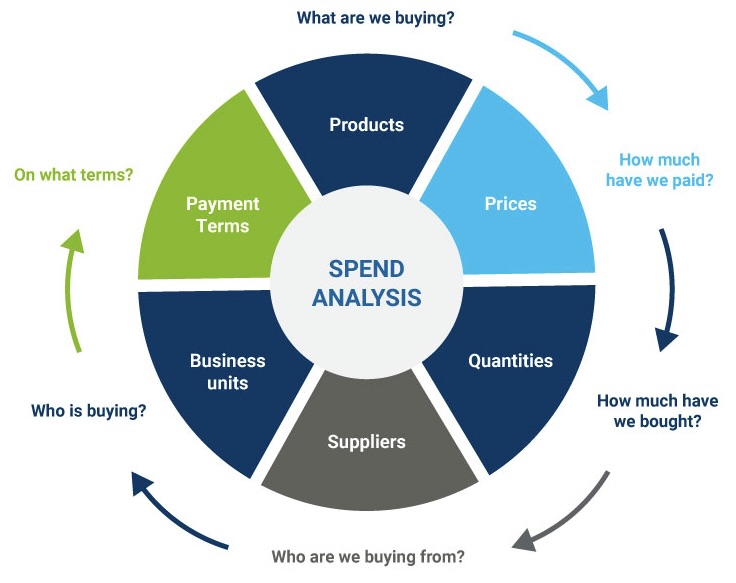

Spend Analysis

Every dollar spent tells a story and understanding that story is key to improving procurement. By knowing exactly where your money goes, you can make smarter decisions, reduce unnecessary costs, and turn spending into a strategic advantage.

Identifying Spending Patterns

To identify spending patterns in procurement, organizations must centralize and clean spend data, categorize purchases, and analyze historical trends to uncover inefficiencies and cost-saving opportunities. By leveraging AI-driven analytics, dashboards, and benchmarking against industry standards, teams can detect maverick spend, forecast future trends, and optimize supplier relationships. Identifying these patterns enables strategic sourcing, better contract negotiations, and improved cost control, ultimately enhancing procurement efficiency and business value.

Finding Cost-Saving Opportunities

After identifying spending patterns, the next step is to cut costs and improve efficiency. One of the most effective ways to do this is by consolidating suppliers. Working with fewer, more strategic partners can increase spend leverage, unlock volume discounts, and simplify procurement management.

Optimizing inventory is also key to cost savings. Just-in-time (JIT) inventory, vendor-managed inventory (VMI), and consignment models help reduce excess stock, free up cash flow, and minimize storage costs. With VMI, suppliers monitor stock levels and replenish inventory as needed, reducing the burden on internal teams. Consignment models go a step further by keeping inventory on-site but owned by the supplier until it’s used, lowering upfront costs and financial risk.

Beyond inventory, improving spend compliance ensures that purchases align with preferred suppliers and negotiated agreements, cutting down on unnecessary costs. Finally, shifting focus from unit prices to total cost of ownership (TCO) helps businesses account for logistics, maintenance, and long-term expenses, leading to smarter, more strategic procurement decisions.

Contract Management

Effective contract management keeps your procurement process smooth and risk-free, yet 90% of professionals find contracts difficult or even impossible to understand. Simplifying your contract management system ensures you know exactly when renewals are due, preventing last-minute chaos and costly mistakes. By making contracts easier to track and staying proactive, you can streamline operations and keep your business running efficiently.

Contract Lifecycle Management

Managing procurement contracts efficiently requires a structured approach that goes beyond simply signing agreements. A centralized contract repository ensures that all agreements, terms, and deadlines are stored in a single, easily accessible system. This reduces the risk of missed renewals, overlooked clauses, or expired contracts that could disrupt operations. A well-organized repository also streamlines audits and compliance checks, saving valuable time and allowing procurement teams to focus on strategic initiatives like supplier negotiations and cost optimization.

Beyond storage, proactive contract lifecycle management is essential to maintaining strong supplier relationships and securing favorable terms. Tracking key milestones, such as renewal dates, expiration deadlines, and supplier performance metrics, helps businesses renegotiate agreements before they lapse, ensuring continuity and cost savings. Staying ahead of these critical dates allows procurement teams to improve service levels, mitigate risks, and maintain a smooth, reliable supply chain without last-minute surprises.

Contract Compliance

Even the best contracts are only as strong as their enforcement. Ongoing contract compliance monitoring ensures that suppliers meet agreed-upon terms, preventing unexpected costs, operational disruptions, and quality issues. Regular compliance checks can help identify problems early—such as late deliveries, pricing discrepancies, or quality shortfalls—allowing businesses to address concerns before they escalate. With a structured compliance framework, procurement teams can maintain stronger supplier accountability, drive continuous improvement, and enhance overall supply chain reliability.

By integrating these contract management strategies, businesses can enhance efficiency, reduce risks, and create a more agile and responsive procurement process—ensuring long-term success in an ever-evolving market.

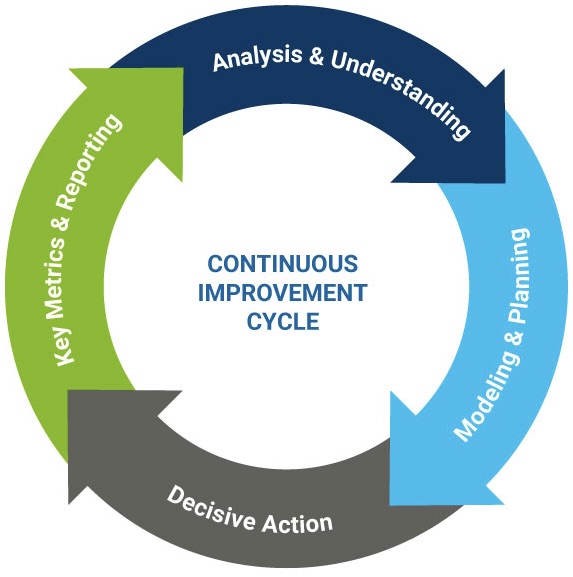

Continuous Improvement

Procurement isn’t a “set it and forget it” process. It requires regular attention to keep things running smoothly. By continuously evaluating and improving your procurement workflows, you can adapt to changes and maintain long-term efficiency.

Regular Process Reviews

Procurement workflows must evolve to keep up with changing business needs, technology, and market conditions. Conducting frequent process reviews helps identify outdated tools, redundant steps, or new inefficiencies that slow operations. For instance, an annual audit may uncover a manual approval process causing unnecessary delays—by implementing automation, teams can streamline approvals, improve turnaround times, and reduce administrative workload. Regular evaluations ensure that procurement processes remain agile, cost-effective, and aligned with organizational goals.

Lean Principles

Lean methodologies focus on eliminating waste and optimizing efficiency. In procurement, this means removing unnecessary steps, reducing excess inventory, and eliminating redundant tasks that add complexity. For example, if multiple departments order the same materials independently, it can lead to confusion, fragmented spending, and higher costs. By consolidating orders and standardizing procurement practices, businesses can leverage bulk discounts, minimize waste, and create a more synchronized supply chain. Applying Supply Chain Consulting can help organizations integrate lean strategies, leading to lower costs, improved agility, and a more strategic procurement function.

Six Sigma

In procurement, consistency and accuracy are critical for minimizing errors, reducing variability, and maintaining supplier reliability. Six Sigma methodologies help refine procurement operations by identifying process inefficiencies, eliminating defects, and ensuring standardization. For example, if purchase order approvals are inconsistent across departments, standardizing the process with clear guidelines and automation can reduce cycle times and enhance compliance. By leveraging data-driven Six Sigma techniques, procurement teams can ensure precision, improve supplier performance, and create a more resilient procurement framework.

By integrating Regular Process Reviews, Lean Principles, and Six Sigma, organizations can build a high-performing procurement function that is cost-efficient, agile, and optimized for long-term success. Strategic improvements today lead to greater efficiency, cost savings, and stronger supplier relationships—ensuring that procurement remains a key driver of business growth.

How to Master Your Procurement Process

Improving your procurement process isn’t just about cutting costs. It’s about creating a robust, efficient system that supports long-term business goals. By leveraging tools like e-procurement platforms, building strong supplier relationships, and regularly evaluating performance, companies can reduce inefficiencies and improve supplier collaboration.

Ultimately, procurement process improvement drives not only cost savings but also operational agility and resilience. Start by mapping your current processes, adopt technologies that enhance visibility, and commit to continuous improvement. With these strategies, your organization will be well-positioned to navigate the challenges of today’s dynamic market.

Jabil offers a variety of procurement services to help businesses enhance efficiency, reduce costs, and build a supply chain that’s ready for the future.