How to Improve Supply Chain Efficiency

How to Improve Supply Chain Efficiency: Streamlining Your Operations for Better Results

No matter the size of your business or the industry you operate in, your supply chain is the lifeline of your operations. It’s the engine that keeps the blood pumping — from supplier to customer, from director to manager, and from expenses to profits. Effective supply chain management is the backbone that ensures your business continues to thrive, quarter after quarter.

Even the most straightforward operations depend on a series of complex, interconnected systems that together form your supply chain.

Inefficiencies in the supply chain can lead to costly delays, higher expenses, and frustrated customers. The good news is that there are clear, actionable steps businesses can take to streamline their supply chains. By optimizing key areas like inventory management, transportation, and supplier relationships, companies can boost performance, enhance customer satisfaction, and unlock long-term growth.

Learning how to improve supply chain efficiency can transform your business, enabling smoother operations, reduced costs, and faster deliveries.

Understanding Your Current Supply Chain

The starting point is to understand your Supply chain end to end. Creating oversight and measuring performance along the supply chain will help to identify which areas to target for improvement, for example -

Supply Chain Mapping

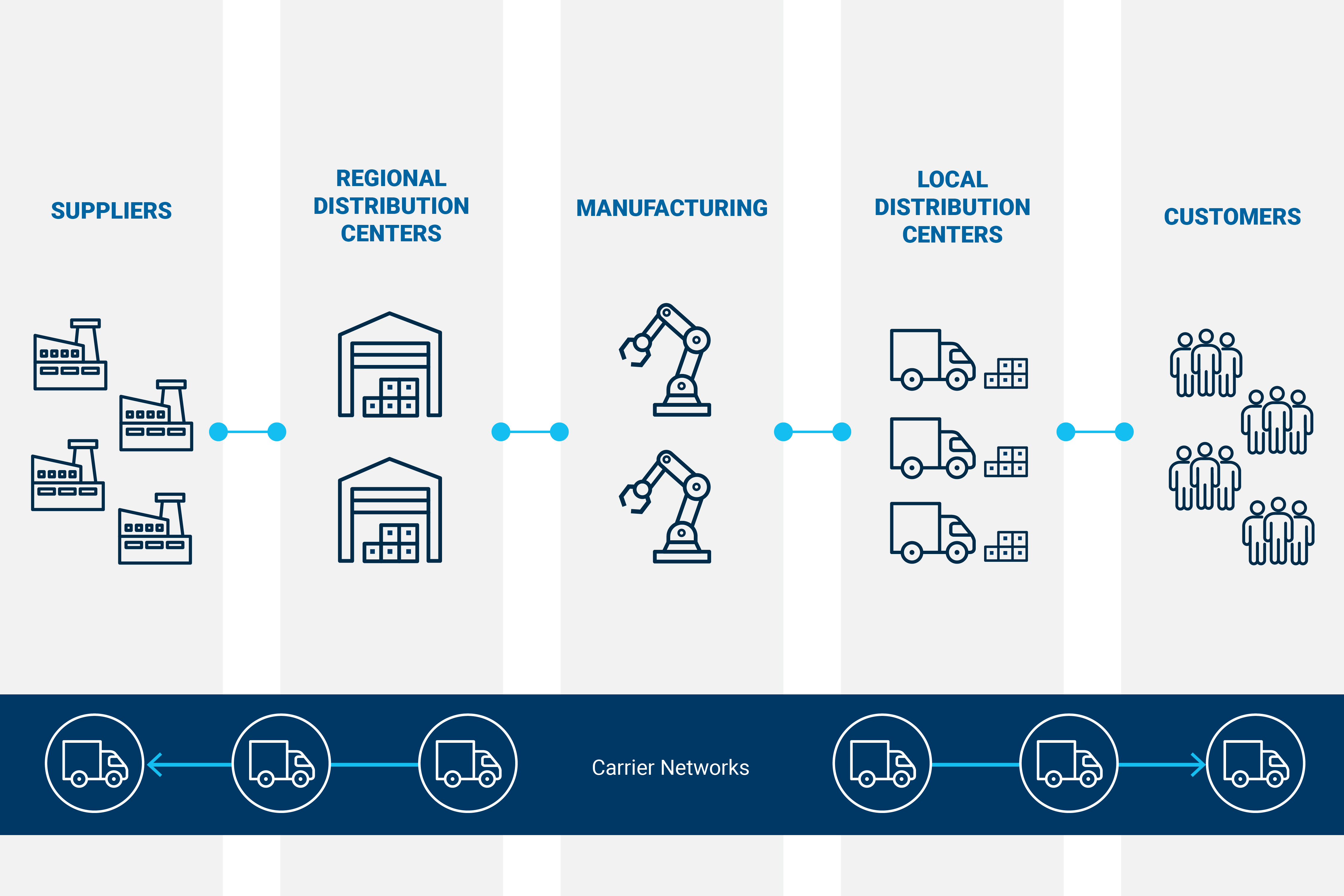

One of the first steps to improving supply chain efficiency is understanding the current state of your supply chain. Supply chain mapping involves visualizing the entire process, from raw material procurement to final delivery. This planning exercise helps businesses identify key stakeholders, processes, and dependencies.

By mapping your supply chain, you can uncover potential bottlenecks and inefficiencies that may be slowing down your operations. For example, you might discover that a particular supplier has longer lead times, causing delays in production. Or you might identify redundant transportation routes that increase costs.

Performance Metrics

To better understand how your supply chain is performing, it’s essential to track key performance indicators (KPIs). KPIs provide valuable insights into various aspects of the supply chain, including inventory management, order fulfillment, and transportation efficiency.

For instance, on-time delivery rate, inventory turnover, and order accuracy are common KPIs used to track the performance of different supply chain processes. Analyzing historical data allows you to identify trends, recognize areas of improvement, and establish performance benchmarks for future success.

Adopting Technology to Enhance Supply Chain Efficiency

Learning how to adopt new supply chain technologies can often be the competitive edge needed to combat disruptions and gain market share from your competitors. Supply chain executives should look for solutions that can enhance visibility, automate tasks, and improve decision-making.

Supply Chain Planning Software

Supply chain planning software enables businesses to improve demand forecasting and inventory optimization. Demand forecasting tools predict future customer demand, helping businesses plan their production and inventory levels accordingly. By aligning production with actual demand, businesses can avoid both stockouts and overstocking, ensuring a balanced supply.

Warehouse Management Systems (WMS)

A warehouse management system (WMS) helps track inventory in real-time, enabling businesses to manage their warehouses more effectively. WMS solutions offer features like order fulfillment tracking, inventory location management, and real-time stock updates, which improve the overall efficiency of warehouse operations.

Transportation Management Systems (TMS)

Transportation management systems (TMS) provide businesses with tools to optimize their transportation networks. With TMS, companies can optimize delivery routes, select the best carriers, and manage freight costs. Route optimization features allow businesses to reduce delivery times and fuel consumption, leading to cost savings and improved customer satisfaction.

Inventory Management Strategies to Optimize Supply Chains

Efficient inventory management is at the heart of improving supply chain efficiency. By reducing excess inventory and improving stock levels, businesses can cut costs and improve cash flow.

Just-In-Time (JIT) & Just-In-Case Inventory Systems

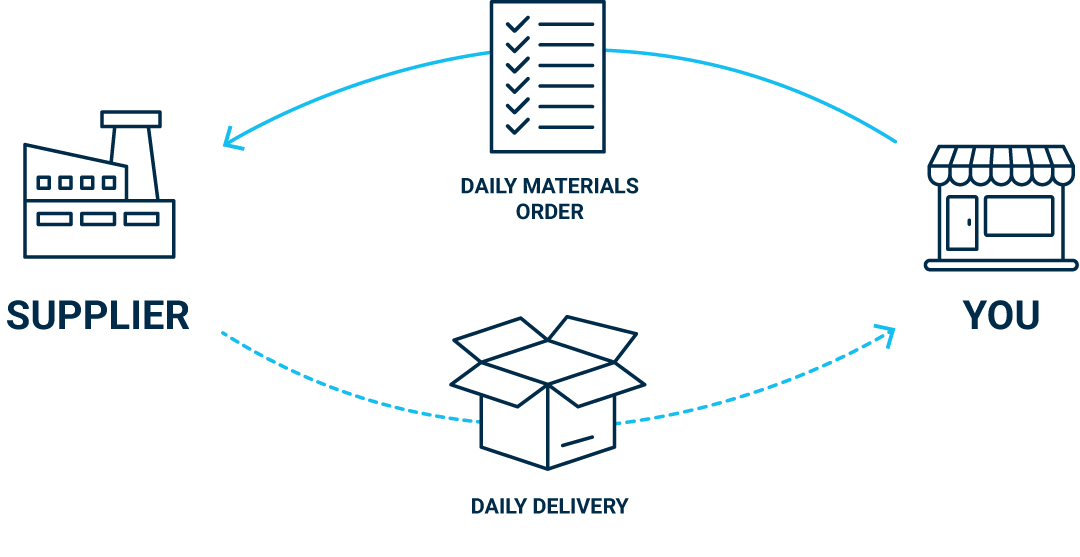

The Just-In-Time (JIT) inventory system minimizes inventory levels by ordering materials only when needed. JIT helps businesses create supply chain resilience by reducing holding costs, avoiding stockouts, and maintaining lean operations. However, JIT requires accurate demand forecasting and a reliable supplier base to function effectively.

The Just-In-Case (JIC) inventory system emphasizes maintaining a buffer stock to guard against potential supply chain disruptions and unexpected spikes in demand. By keeping extra inventory on hand, JIC helps ensure business continuity, reduce the risk of stockouts, and meet customer demands even when uncertainties arise.

Safety Stock Optimization

While JIT works well in many situations, businesses should also consider safety stock optimization. Since the pandemic, safety stock has become a critical buffer, helping protect against unexpected fluctuations in demand. By calculating optimal safety stock levels, businesses can strike a balance between supply and demand, avoiding both overstocking and understocking.

Demand Forecasting

Demand forecasting plays a critical role in both JIT and safety stock optimization. Using historical sales data, market trends, and other predictive tools, businesses can forecast demand and adjust inventory levels accordingly. Accurate demand forecasting reduces the likelihood of stockouts and improves overall supply chain efficiency.

Inventory Turnover

Tracking inventory turnover is essential for understanding how efficiently your inventory is moving through the supply chain. A higher inventory turnover rate indicates that products are selling quickly, and that inventory is being efficiently managed. By focusing on increasing turnover, businesses can improve cash flow, reduce storage costs, and streamline their operations.

How to Improve Supply Chain Efficiency through Supplier Relationship Management

Strong supplier relationship management (SRM) is essential for maintaining supply chain efficiency and controlling costs. Cultivating lasting partnerships with suppliers can ensure a steady flow of materials, improve resilience during disruptions, and reduce risks.

Building Strong Partnerships

Collaborative planning, forecasting, and replenishment (CPFR) is a strategy that fosters open communication and joint planning between buyers and suppliers. By sharing information on inventory levels, demand forecasts, and production schedules, businesses can align their operations with suppliers to create a more efficient supply chain. Walmart’s use of CPFR in the late 1990s improved in-stock levels for products like Listerine, raising the average from 87% to 98%.

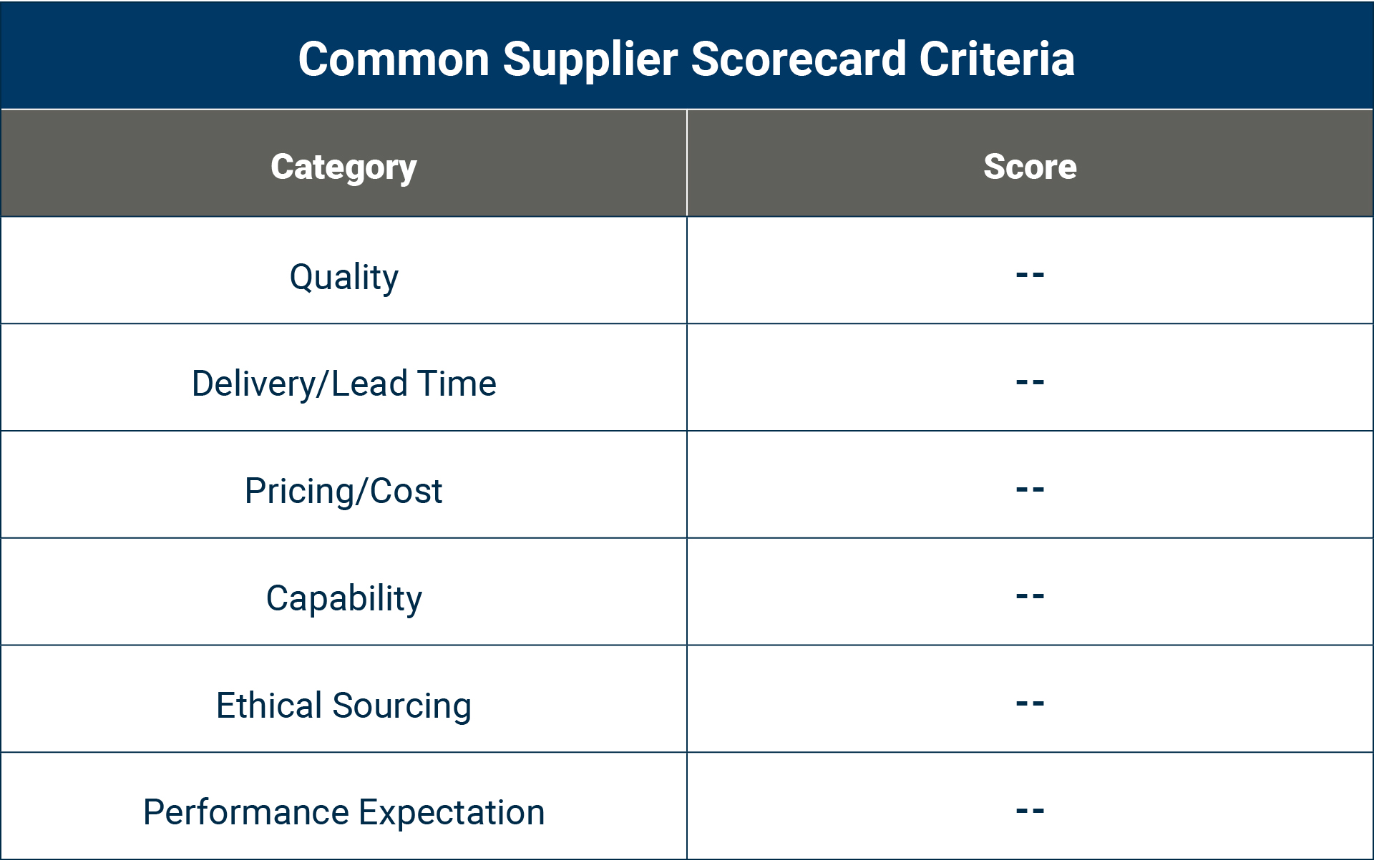

Supplier Performance Evaluation

Regularly evaluating supplier performance helps ensure quality, mitigate risks, and improve procurement efficiency. Metrics like lead time, product quality, and responsiveness provide valuable insights, while tools like supplier scorecards highlight areas for improvement. Transparent, two-way evaluations strengthen supplier relationships and drive continuous improvements, resulting in a more resilient and efficient supply chain.

Supplier Diversity

Diversifying your supplier base is a great way to reduce the risks of depending too much on one supplier. It helps businesses manage potential disruptions like geopolitical events, natural disasters, or financial instability. In fact, 68% of organizations globally have felt increased pressure to prioritize supplier diversity since 2021, showing just how important it’s become in building a more resilient supply chain.

Risk Management Tactics for a More Resilient Supply Chain

You might be all for taking risks in your personal life, but when it comes to your supply chain, risk management is key. Instead of rolling the dice, effective risk management helps you stay ahead of disruptions and ensures your supply chain remains smooth, no matter what surprises come your way.

Identifying Potential Risks

Supply chains face numerous risks, including supply disruptions, natural disasters, geopolitical events, cybersecurity threats, and global pandemics. Proactively identifying these risks through regular risk assessments helps businesses anticipate challenges and develop unique mitigation strategies for any potential outcome.

Developing Contingency Plans

To ensure business continuity, companies must develop contingency plans that outline backup suppliers, alternative transportation routes, and emergency protocols. By preparing for potential disruptions, businesses can minimize the impact of unforeseen events and keep their operations running smoothly.

Risk Assessment and Mitigation

Risk management is an ongoing process that requires regular reviews and updates. By continuously assessing potential risks and adjusting contingency plans as needed, businesses can stay ahead of disruptions and maintain supply chain efficiency.

Making Your Supply Chain Work Smarter, Not Harder

No two supply chains are the same, and the pressure on different parts can shift at any moment. Keeping a clear, real-time view of your operations ensures you can respond quickly and implement efficient solutions before small issues become big problems.

By focusing on strategies like supply chain mapping, embracing new technologies, fine-tuning inventory, and building solid supplier partnerships, you’re setting up your business for smoother operations and a more resilient future.

An efficient supply chain keeps things simple: manage your inventory wisely, reduce risks, and work closely with reliable suppliers. Using tools like planning software, warehouse systems, and transportation management helps you stay on top of things and make smart decisions. Checking how your suppliers are performing and having backup plans ready keeps you flexible when challenges pop up.

When you get these pieces right, you improve cash flow, keep your customers happy, and set your business up for long-term success.