Materials Innovation Center

Delivering Material Innovation through Research and Development for Polymeric Materials

Custom Materials for Additive and Traditional Manufacturing

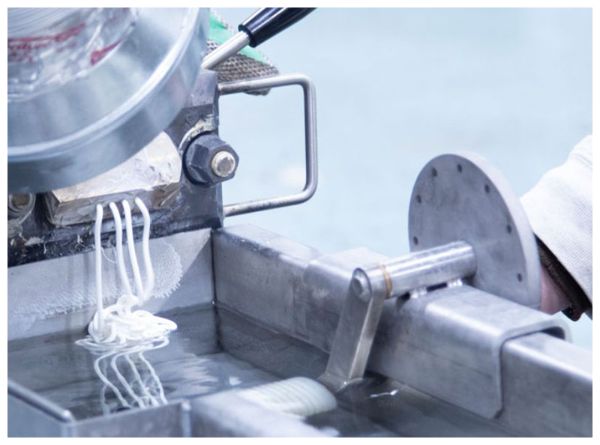

Our custom materials are created, tested and validated at Jabil’s Materials Innovation Center in Chaska, Minn., where polymer formulations, compound developments, material system integration and Quality Management System (QMS) certifications are completed from start-to-finish under one roof. Highly experienced additive manufacturing engineers, chemists, materials scientists and production experts leverage Jabil’s innovations in materials science to oversee each step of the beaker-to-box process of developing customized pellets, powders, and filaments, developed to meet the specialized needs of our customers.

Complete Manufacturing Materials Solutions

From formulation and compounding, to conversion and production. One location for quick turnaround.

46,000 square foot facility, ISO 9001 Registered.

Our engineered materials can be qualified on any open 3D printer system. To date, qualified printer systems include Ultimaker, LulzBot, Farsoon and EOS platforms.

End-to-End Capabilities

Polymerization

- Benchtop to Pilot Scale

- WW Production Partners

Analytical Testing

- Fully equipped analytical lab

Formulation & Compounding

- SME formulators

- Expertise in Flame, Food contact, Healthcare, electrical, etc.

Form Factor Conversion

- Single Screw Extrusion

- Chemical Precipitation

- Mechanical Grinding

Material System Integration

- ISO controlled material/system integration for printer/material setup card creation

Quality Control

- ISO 9001 Certified

- Per spool/power lot traceability and COC available.

- Fully traceable supply chain

Get In Touch

Customizing materials to meet our customer's goals. Get custom materials in weeks not months.