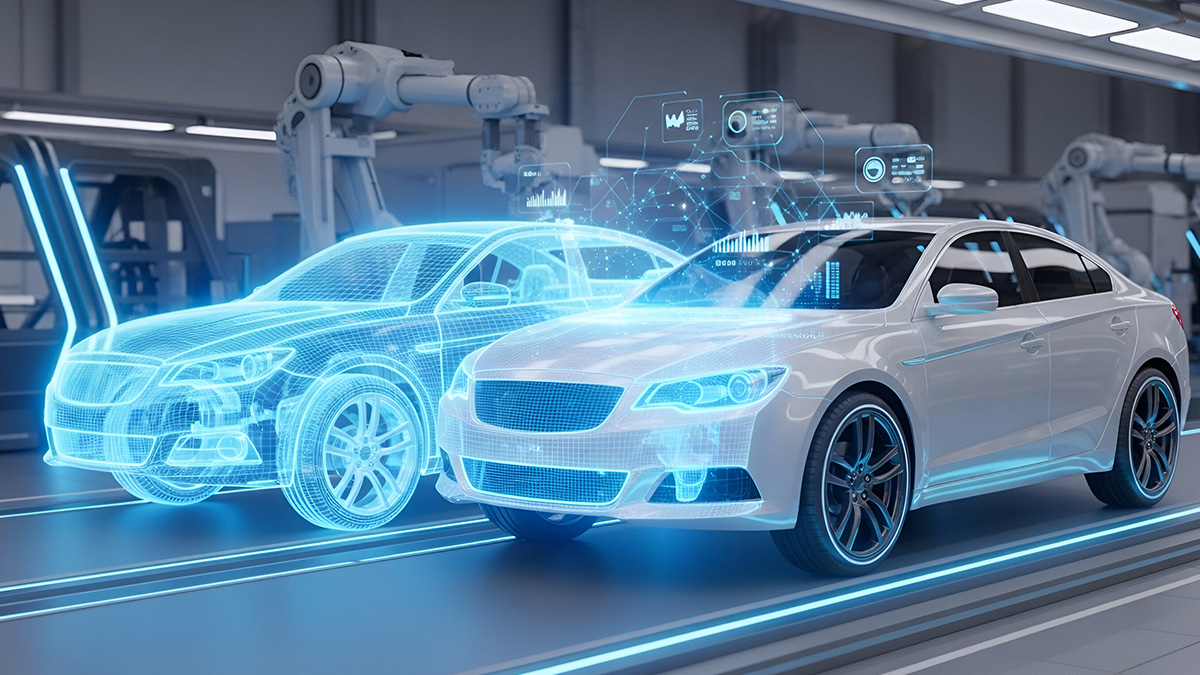

The automotive industry is entering an AI-native era, where digital design, smart factories, and software-defined vehicles (SDVs) form a seamlessly connected ecosystem. The impact will be dramatic and measurable: faster product launches, improved quality, reduced risk, and vehicles that continuously enhance their performance over time.

Over the past six months, leading OEMs and Tier 1 suppliers have moved beyond AI pilot programs to scaled deployments, in areas such as AI-assisted simulation, digital twins, computer vision, edge AI on the shop floor, and data-space collaboration.

AI is strengthening the link between engineering, manufacturing, supply chain, and the driver experience by leveraging real-time data to drive higher quality and dependability from the very first build. Once vehicles hit the road, AI continues to deliver value — predicting maintenance needs, supporting advanced safety systems, and generating insights that elevate the ownership experience.

Below, we explore some of the biggest opportunities created by AI across the automotive product lifecycle.

AI‑Accelerated Design: Faster Design Cycles, Increased First‑Time Quality

Automotive engineers have long used advanced tools to validate concepts. But what once required months of design, prototyping and analysis may soon be completed in hours. AI tools supporting simulation of test environments, sensor behavior, and workflow efficiencies will accelerate performance analysis, reduce dependence on physical prototypes, and enable faster, more informed decisions.

Engineering teams at vehicle manufacturers and their technology suppliers will increasingly rely on AI‑powered simulation and digital twin workflows to validate complex systems such as optics-based driver assistance systems, battery packs, and thermal management. Performance and quality checks will occur before a physical prototype is even created, improving first-time quality and reducing costly iterations.

Advanced AI can even correlate vehicle-level testing with subsystem performance and manufacturing data, giving engineers deeper insights earlier in the process. With AI handling repetitive tasks, engineers can focus on higher-value innovation and decision-making, accelerating the entire product development lifecycle.

New offerings like Siemens’ PAVE360 Automotive promise “day‑one” full‑system virtual integration, reducing setup from months to days while allowing early software validation — shortening development times and improving first‑time right outcomes.

Meanwhile, NVIDIA and Siemens have previewed an AI‑era industrial tech stack that connects real-world engineering with photorealistic digital twins allowing teams to interact with live engineering data in immersive environments. The result: faster design decisions, fewer late changes, and more reliable production ramp‑ups.

AI-Enabled Manufacturing: Real-Time Quality, Flexibility, and Efficiency

AI-assisted manufacturing lines and quality testing are already established across many advanced automotive manufacturing lines, driving significant improvements. Where real-time analytics enhance decision-making on the line by providing immediate visibility into process performance. Not only does this accelerate the stabilization of production faster, it also helps maintain quality throughout the ramp-up.

AI-powered anomaly detection flags potential issues before they impact manufacturing performance, while predictive maintenance identifies the right moments to service equipment, reducing downtime and extending asset life. High-resolution optical systems and machine learning work together to catch defects early in production, enabling rapid corrections and preventing problems from escalating.

Beyond machine learning, generative AI expands workforce capabilities by streamlining knowledge access and standardization. Operators and technicians can use proprietary GenAI tools to instantly access official documentation, troubleshooting guidance, and proven processes. This closes knowledge gaps, speeds onboarding, and ensures best practices are replicated consistently across all facilities, regardless of geography or product complexity.

At Jabil, we’re leveraging these technologies across global operations. Automated Optical Inspection (AOI), combined with more than 25,000 robots and over 2,000 trained engineers, ensures accurate, high-speed production of our customers’ technology. Additional platforms, such as Jabil’s AI-powered Debug Tool, centralize diagnostics and repair workflows, accelerating issue resolution and improving visibility across sites.

AI is also enabling flexible vehicle production mix in some plants. For example, Toyota’s K‑flex transformation at Georgetown, Kentucky, integrates autonomous material movement (skillets), AI‑assisted choreography, and flexible line design to build SUVs, hybrids, EVs, and sedans on a single line. Reports highlight door‑to‑door assembly strategies, edge‑connected robots, and Wi‑Fi‑based coordination, signaling operational maturity.

Vehicle Digital Twin: Fewer Recalls, Faster Containment, and Improved Customer Satisfaction

Beyond accelerating design and production, AI is enabling one of the most transformative innovations in automotive development: the vehicle digital twin. This is a precise, data-rich virtual replica of a vehicle that evolves throughout its lifecycle.

A dynamic digital twin captures everything about the vehicle, from individual components deep in the supply chain to manufacturing processes, driving habits, and even regulatory data on safety and performance. This continuously updated real-life model unlocks new levels of proactive quality control, predictive maintenance, and agile production.

By integrating field data with design and manufacturing insights, manufacturers will be able to identify and resolve issues much faster. We’re evolving towards a scenario where real-time intelligence would allow factories to quickly run root-causes analysis of production and component performance — thereby accelerating issue resolution. Once the vehicle reaches the consumer, the digital twin could continue to mirror its condition, collecting data on driving performance, maintenance needs, and overall health.

The most transformative change would be created via a closed loop between factory and road. Digital twins will also reveal patterns of when components fail or require service, helping owners avoid unexpected breakdowns and improving long-term vehicle reliability. This visibility will enable targeted recalls for specific vehicles instead of costly blanket recalls across entire platforms. And will also support predictive maintenance, improving customer ownership experience, and satisfaction.

Catena‑X is the first end-to-end, collaborative and open data ecosystem for the automotive industry, connecting all players along the value chain. It secures data exchange across the entire value chain to address urgent challenges within the automotive industry, including product carbon footprint, end-to-end traceability, collaborative quality management, and battery passports.

In one documented case leveraging the Catena-X platform, a recall preliminarily scoped at 1.4 million vehicles was narrowed to just 14 after cross‑company data sharing, illustrating the cost and reputational protection that trusted data collaboration can deliver.

Cybersecurity and Governance: The Backbone of AI Adoption

As the automotive industry embraces AI, cybersecurity and data governance have shifted from technical requirements to strategic imperatives. The stakes have never been higher. A single vulnerability can disrupt production and erode consumer trust.

To protect against this risk, industry players across the value chain are embedding security and governance into every layer of their operations, transforming these disciplines into foundational pillars of innovation. Cybersecurity is embedded from the earliest design stages and reinforced throughout the entire product lifecycle. This means integrating strong safeguards into system architecture, development practices, and verification processes to protect operational and customer data.

Equally critical is the quality and governance of data powering AI. Effective AI depends on trusted, well-governed data. Without clear frameworks for accuracy, consistency, and traceability, even the most advanced algorithms fall short. Industry leaders are adopting governed ecosystems like Catena-X to maintain a “chain of trust” from shopfloor telemetry to cloud analytics. This ensures that insights and automation are meaningful, dependable, and compliant, supporting everything from predictive maintenance to regulatory reporting.

Recent certification milestones highlight how cybersecurity is now a prerequisite for automotive production. Standards like ISO/SAE 21434 define how to manage cybersecurity throughout the entire vehicle lifecycle — from design to decommissioning. It also supports compliance with UNECE R155 and R156, which are United Nations regulations requiring cybersecurity and software update management for vehicles sold in many global markets.

At Jabil, a defense-in-depth strategy safeguards data and systems across global markets through four core pillars: identity access management, data protection, security monitoring and intelligence, and security incident response. These capabilities — supported by advanced technologies, specialized expertise, and ongoing policy awareness training — help us mitigate risk and maintain compliance.

Enabling A Connected AI Ecosystem

Artificial intelligence is rapidly transforming automotive manufacturing, creating a seamlessly connected ecosystem that will link design, production, and vehicle performance. The industry is moving quickly from experimentation to scaled deployment of AI-powered solutions such as digital twins, real-time analytics, computer vision, and governed data spaces. These advances will deliver tangible benefits: faster product launches, higher first-time quality, more flexible and resilient factory operations, and dramatically improved recall containment.

With robust cybersecurity and data governance now serving as the foundation, automakers are not only accelerating innovation but also building trust and regulatory readiness for the vehicles of tomorrow. The result is a smarter, safer, and more agile automotive industry — where AI drives excellence at every stage.

With robust cybersecurity and data governance now serving as the foundation, automakers are not only accelerating innovation but also building trust and regulatory readiness for the vehicles of tomorrow. The result is a smarter, safer, and more agile automotive industry — where AI drives excellence at every stage.

How can Jabil help you meet your automotive manufacturing goals? Contact us.

No matter how complex or demanding the project, Jabil's automotive and transportation team is helping today’s innovators solve it. Get started with a trusted partner.