Automation

Accelerating time-to-market with scalable, quality-focused automation

Automation projects often begin with high expectations. However, OEMs frequently encounter two common challenges: unclear requirements that don’t align with technical specifications, and the complexity of integrating proprietary systems without disrupting operations. When these issues aren’t addressed early, they can cause delays, increased costs, and compromised outcomes.

At Jabil, we help our customers define clear automation goals and align them with the right technical solutions, including precision automation. Our deep engineering and hardware expertise, combined with a consultative approach, ensures we deliver solutions that are right from the start and built to last.

Automation is embedded into our factory systems through standardized processes and rigorous design guidelines. As new processes are developed and validated, they’re deployed across our global network of over 2,000 engineers and technicians — ensuring consistent performance across every site and faster time to market.

Our flexible, modular systems, powered by Jabil’s proprietary automation software, integrate seamlessly with your existing tools and technologies, enhancing traceability, data control, and overall performance.

Guided by our principles — simplify, optimize, standardize, and automate — we deliver scalable solutions that drive measurable impact from day one.

Our Automation Platforms

We work closely with our customers to develop tailored automation strategies that align with their product specifications, ensuring with the technologies and capabilities for optimal performance.

Mid-Speed Automation

Our mid-speed automation gear leverages proven application modules available on the market. Designed with simplicity in mind, it features intuitive operations and maintenance procedures. More than 80% of the system is reconfigurable, enabling rapid adaptation to new applications as your production needs evolve.

Manual Workstation Automation

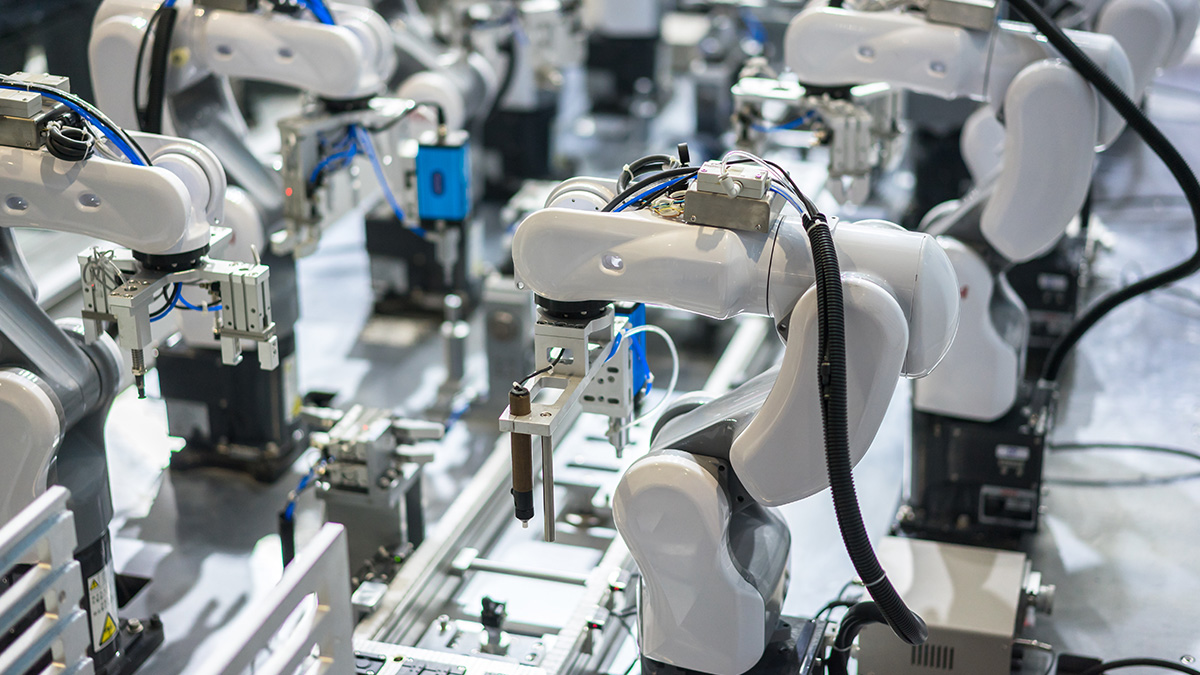

This cost-effective automation includes tools like robotic arms. It can be used for a wide range of simple tasks like palletizing and inspection, freeing up employees for higher value tasks.

High-Speed Automation

With this technology, Jabil’s core competency lies in our ability to partner with and onboard key suppliers to support complex, high-throughput applications like injection molding.

End-Market Specific Automation

Technologies like active alignment and customized semi-cap manufacturing solutions are purpose-built to serve the needs of the industries we support — including automotive, transportation, consumer electronics, and capital equipment — ensuring precision, scalability, and performance where it matters most.

Warehouse Automation

Jabil uses advanced technologies like autonomous guided vehicles (AGVs) and automated storage and retrieval systems (ASRS) in its operations to optimize material movement and storage. These systems increase safety, enable real-time traceability, reduce manual handling costs, and simplify warehouse operations for faster, more accurate performance.

PRECISION AUTOMATION SOLUTIONS

Jabil’s precision automation teams provide custom automation solutions for assembly processes that require unparalleled accuracy, consistency, and efficiency. We take on projects from simple pick-and-place production lines using industry-standard robots to micron-level alignment applications requiring custom designed vision and motion systems. Jabil can design and fabricate the ideal system required to build your next-generation products across industries such as automotive, healthcare, semiconductors, and other electronics to submicron accuracy.

How we do it

Quality-Driven Automation Framework

With nearly 60 years of experience in electronics and mechanical manufacturing, Jabil continues to evolve and strengthen its automation capabilities. Our deep cross-industry expertise in machine safety and compliance makes us a trusted partner for protecting both people and brands.

We’ve developed a gated lifecycle management system and a standardized ruleset for Design for Manufacturing (DfM) and Design for Automation (DfAA) to mitigate risk and integrate quality requirements throughout the production process. From concept to ramp, we leverage our zero-defect mentality to maintain the highest levels of quality at each stage of automation solutions delivery.

Standardized, Repeatable Processes

At Jabil, automation is designed to scale. Every new process or application is built on data-driven operating procedures and refined for repeatability. Once these automation solutions are validated for performance and reliability, they’re embedded into our global operations, allowing customers at any Jabil location to benefit from innovations developed across our footprint. This connected approach ensures a consistent experience from site to site, while the standardization of tools and processes boosts efficiency and accelerates time-to-market.

Cost Optimization

We minimize capital expenditures (CapEx) and optimize the total lifecycle costs of Jabil-developed automation gear by creating reusable, scalable solutions that can be repurposed for a wide variety of applications. To further streamline engineering efforts and accelerate time-to-market, we incorporate validated, commercially available components where possible. By partnering with trusted equipment and software vendors, we strategically combine internal and external automation solutions to deliver fast, cost-effective results for our customers.

Software to Enable Scale and Visibility

Our reusable, modular automation designs are built on Jabil’s proprietary automation software platform. This flexible software allows us to connect automation processes through a single control point or many for improved traceability, data control and management, and performance reporting. Our teams can even collaborate with customers to provide software integration when their own customer platforms are required in the automation process.

Dedicated Jabil Resources

Our unique customer engagement model is based on close partnership and collaboration between customers and a dedicated business unit leader who serves as the single point of contact at Jabil. Business unit leaders guide the creation of workcells that align with each customer’s specific production requirements, ensuring the right expertise and capabilities are in place to flex, scale, and adapt as those needs change.

Global Automation Talent

Our people are at the heart of Jabil’s automation solutions. Across our global sites, we’ve built a strong talent pipeline backed by regional automation centers and a network of sector- and technology-specific subject matter experts (SMEs), serving our customers with expertise when and where they need it.

SMEs are strategically located in key regions to support the specific automation needs of local sites and industries. These experts, along with our Centers of Excellence, provide governance, share best practices, and drive consistency across all Jabil locations. Thousands of automation engineers and technicians work together across our global sites as part of a standard operating model for delivering safe, capable automation solutions.

How can Jabil bring your product vision to life using automation?

Contact us.