Custom Precision Automation

Advanced custom automation for your products

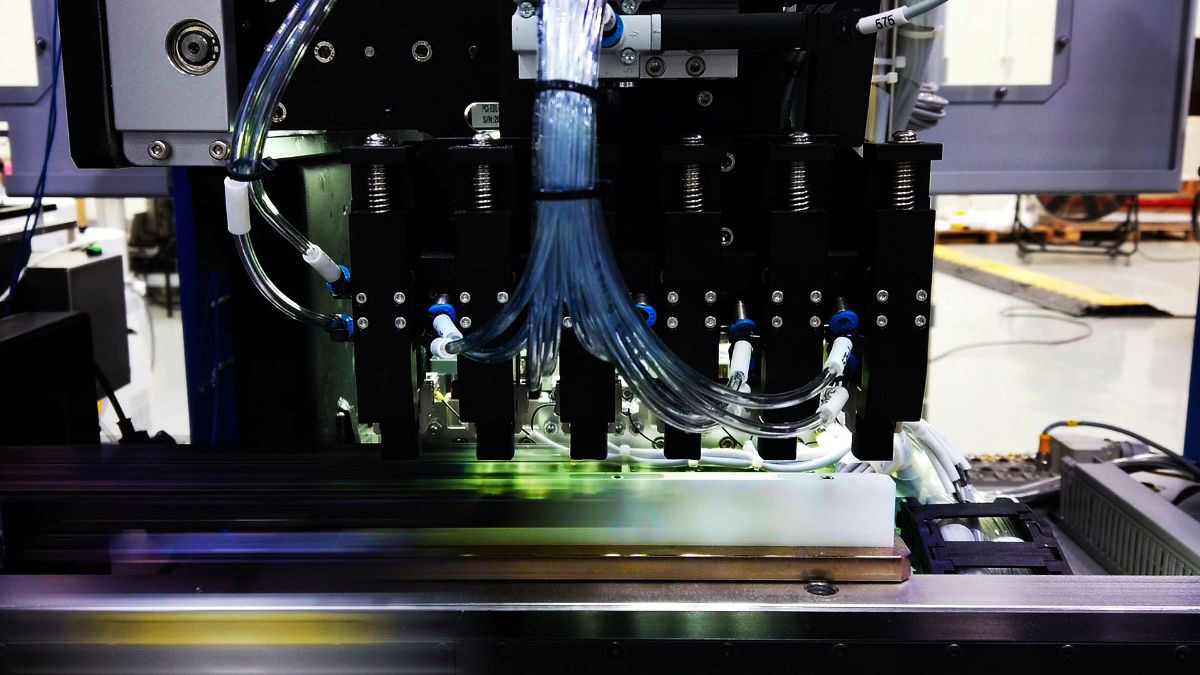

Jabil’s precision automation team has the expertise and experience to meet the specifications of your precision alignment, handling, or assembly processes. Your engagement with Jabil starts with a structured design process led by expert project management and cross-functional engineering teams. Depending on your needs, we can design using standard assembly robots and assembly systems or use equipment capable of providing the submicron accuracy required for your next-generation products.

Our teams develop custom projects across a broad range of industries, from automotive and healthcare to VR headsets and wearables. With precision automation from Jabil, you are investing in proven experience, cutting-edge capabilities, and dedicated customer service. Our team works with you to ensure we deliver the quality equipment you need, on time, and backed by our attentive customer care for installation, testing, and ongoing support.

Our Capabilities

Extend your automation possibilities with Jabil’s cutting-edge solutions

-

Motion Control

-

Precision Alignment

-

Inspection & Test

-

Automation Software

-

Robotic System Integration

-

Battery Module Assembly

Industries Served

Improve your products with custom precision automation

Automotive

Consumer

Healthcare

Optics

Renewable Energy

Semiconductor

Jabil Precision Automation Platforms

CP150 Series Automation System

The CP150 automation platform is OSHA- and ANSI-compliant and offers future-proof flexibility to any production line by delivering a highly modular, scalable system that addresses a variety of automation needs. The CP150 delivers enhanced capabilities in vision-based alignment, lamination, metrology, optical inspection, and high-speed final assembly. This machinery provides valuable benefits, including configuration flexibility and multiple levels of automation. It is re-deployable and enables rapid changeover for various applications.

CP100 Series Automation System

Jabil’s CP100 platform provides a robust machine platform for general assembly automation applications. The platform can support Cartesian, SCARA, or 6-axis manipulators; edge belt or pallet conveyors; and a host of different end effectors. This platform delivers key capabilities in pick-and-place action, P2P soldering, screw fastening, label placement, vision-based alignment, and precision dispensing. This is a re-deployable system that enables easy changeover of applications and supports semi-manual to fully automated processes.

Our Process for Custom Projects

Jabil’s engineers and experts serve as an extension of your team, working closely with you to ensure success throughout the engagement.

ENGAGE

Design for Automated Assembly (DfAA)

Jabil’s design engineers can provide your team with recommendations for industrializing your product design to enable automated assembly and more to improve production quality and yield.

Brainstorm & Concepting

Collaborate on a conceptual solution for the problem at hand with a multi-discipline team.

Solution Proposition

Together, we review the solution concept to ensure alignment, then we develop a formal written proposal with the complete scope of work and pricing.

EXECUTE

Project Kick-off

Jabil project managers and engineers meet your team to launch the project, reconfirm expectations, and set the timeline.

Collaborate & Innovate

Engineering team goes from concept to working design model with frequent communication and collaboration at the level you require.

Design Review

The design review checkpoint ensures the solution is fully aligned with your production needs and project specifications.

System Build

Jabil begins procuring materials and fabricating parts to build your machine. Motors, sensors, and actuators are installed, wired, and calibrated.

System Programming and Start-up

Our expert software engineers load and test program material and bring the machine to life.

Testing

Each system is rigorously tested for proper functionality and optimum performance by seasoned test engineers.

Factory Acceptance Test

Factory Acceptance Testing is conducted to confirm the solution matches what was specified, proposed, and agreed to at design review.

Project Management

Project management staff diligently schedules each project to ensure timely delivery. Costs are closely tracked with enterprise-level ERP system.

SUPPORT

Equipment Installation

Our engineers and techs work side-by-side with your team to deliver, install, and verify your machine for peak performance.

Training & Documentation

Our staff will train your teams to maximize the use of your equipment. We provide a full documentation package to support and maintain the equipment for years of service.

Service & Guidance

You get 24/7 support by phone and field service engineers provide on-site help, additional training, or upgrades.

How can Jabil solve your precision automation challenges?

Get in touch with one of our automation experts.