INSIGHT

Scalable, strategic business models to meet your manufacturing needs

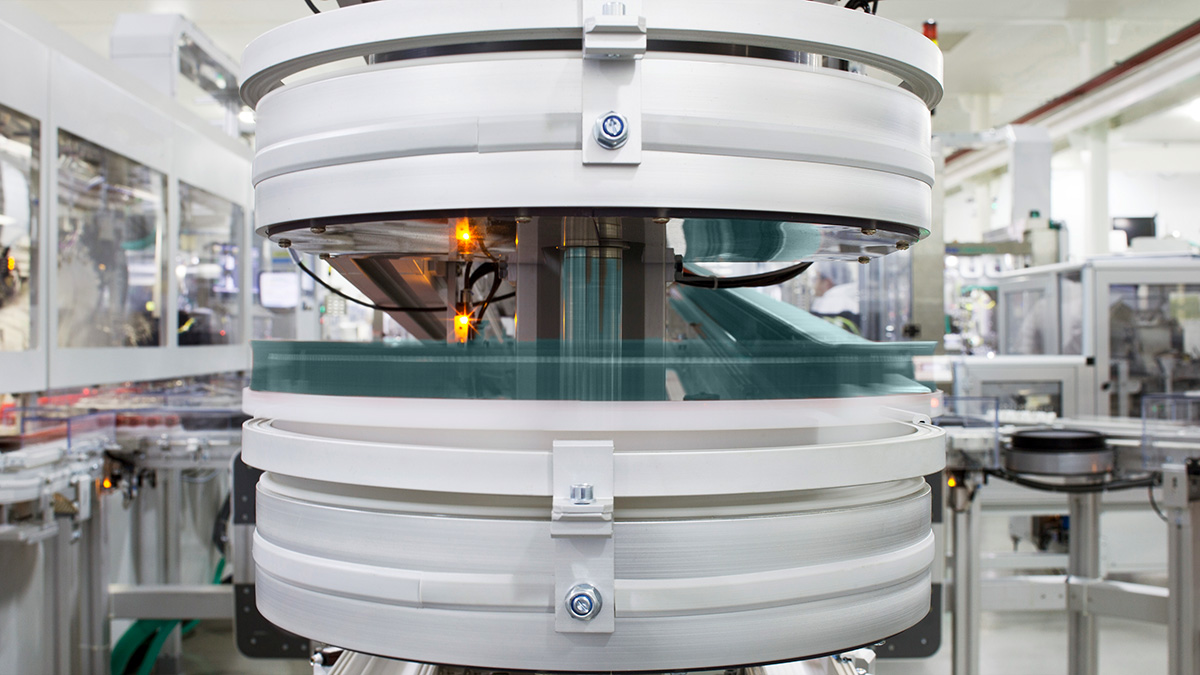

One-size-fits-all manufacturing won’t cut it in today’s innovation-driven, hyper-competitive global business landscape. Agility, scale, and speed-to-market are critical. Quality, reliability, and compliance are even more important.

That’s why Jabil offers a full spectrum of manufacturing models tailored to meet your precise production needs now and into the future — no matter where you are in your product journey. Jabil fulfills your requirements with predictable, customized manufacturing solutions, keeping you informed and in control.

Manufacturing Fulfillment Models: The Choice is Yours

Prototyping

|

Jabil offers quick-turn, high-quality prototyping services tailored for proof of concept, minimum viable product, or design simulations. This approach enables thorough, cost-effective testing and validation, while ensuring a seamless transition to volume production — without incurring the costs associated with finished goods inventory.

Pick to Ship

|

The pick-to-ship model is ideal for companies with stable demand that maintain inventories of pre-manufactured goods ready for immediate shipment. Jabil pulls products from stock, packs them, and ships them directly to customer-designated destinations for efficient order fulfillment.

Build to Forecast

|

The build-to-forecast model supports companies with predictable demand by leveraging historical sales data and demand forecasts to guide production volumes. This model enables economies of scale, optimized inventory levels, and faster delivery through pre-planned, bulk manufacturing.

Build to Order

|

In the build-to-order model, product manufacturing begins only after a customer's order is received, making it ideal for companies with highly variable demand. This approach supports smaller, custom production runs and offers cost savings by minimizing inventory at both the subassembly and assembly levels.

Configure to Order

|

Configure-to-order also supports variable demand but typically allows for faster lead times than build-to-order. In this model, Jabil maintains inventories of components or semi-finished products, enabling customers to select features or configurations to meet their unique requirements before final assembly and shipment.

Quality is foundational to who we are at Jabil — guiding every decision, every action, and every outcome across our global sites. Our commitment to perfect quality offers our customers a safe pair of hands, protecting their brands and innovations while ensuring compliance with rigorous global regulatory standards.

Quality is everyone’s responsibility, at every level of the organization. From senior leaders to frontline teams, we take personal accountability, measure performance, and celebrate excellence. Grounded in consistent, observable behaviors, Jabil’s zero-defect culture ensures we get it right from the start.

From first concepts to full manufacturing at scale, quality is built into every step of our process. Jabil teams rely on our trusted global quality management system to drive consistency, uphold compliance, and enable continuous improvement. Together we are delivering a future of manufacturing where excellence is expected, achieved, and sustained.

For nearly 60 years, Jabil has provided agile, advanced manufacturing solutions to the world’s leading brands with unmatched engineering and technical expertise, comprehensive supply chain support, and reliable quality performance and compliance. Our scope of operations includes a global network of 100+ sites, with our 3,000 procurement experts managing more than 38,000 suppliers and $25B in annual procurement spend.

LEARN MOREContact us.

Related Insights