Semiconductor Wafer Handling Solutions

High-performance, custom systems built to your requirements

Jabil’s proven track record in wafer handling automation enables us to serve as a full-service automation integrator for the world’s largest semiconductor manufacturers. By incorporating the latest advancements in wafer handling technologies, our automation platforms deliver high-performance wafer and substrate handling that streamlines the semiconductor manufacturing process.

We build a wide range of wafer handling solutions, from Equipment Front End Modules (EFEM) to full turnkey automation platforms. Whether you’re looking for a basic wafer handling application or a custom solution, Jabil can tailor a solution that’s built to last in the most demanding production environments.

Our Platforms

WaferMate 300 Series Wafer Handling System

The WaferMate 300 is a highly configurable, BOLTS-compatible robotic wafer-handling platform that supports a wide range of semiconductor wafer process tools. It is available in single, dual, and triple load port configurations, primarily for 300mm or smaller wafer sizes. An integrated FFU allows for ISO Class-2 cleanliness. It is SECS/GEM compliant for factory host communication. All Jabil wafer handling systems are compliant with CE and SEMI S2/S8.

.png)

WaferMate 200 Series Wafer Handling System

The WaferMate 200 is a small footprint robotic wafer-handling platform that pairs seamlessly with multiple types of process tools. It can be configured for up to three open cassette placement locations, primarily for 200mm or smaller wafer sizes. All our wafer handling systems are compliant with CE and SEMI S2/S8.

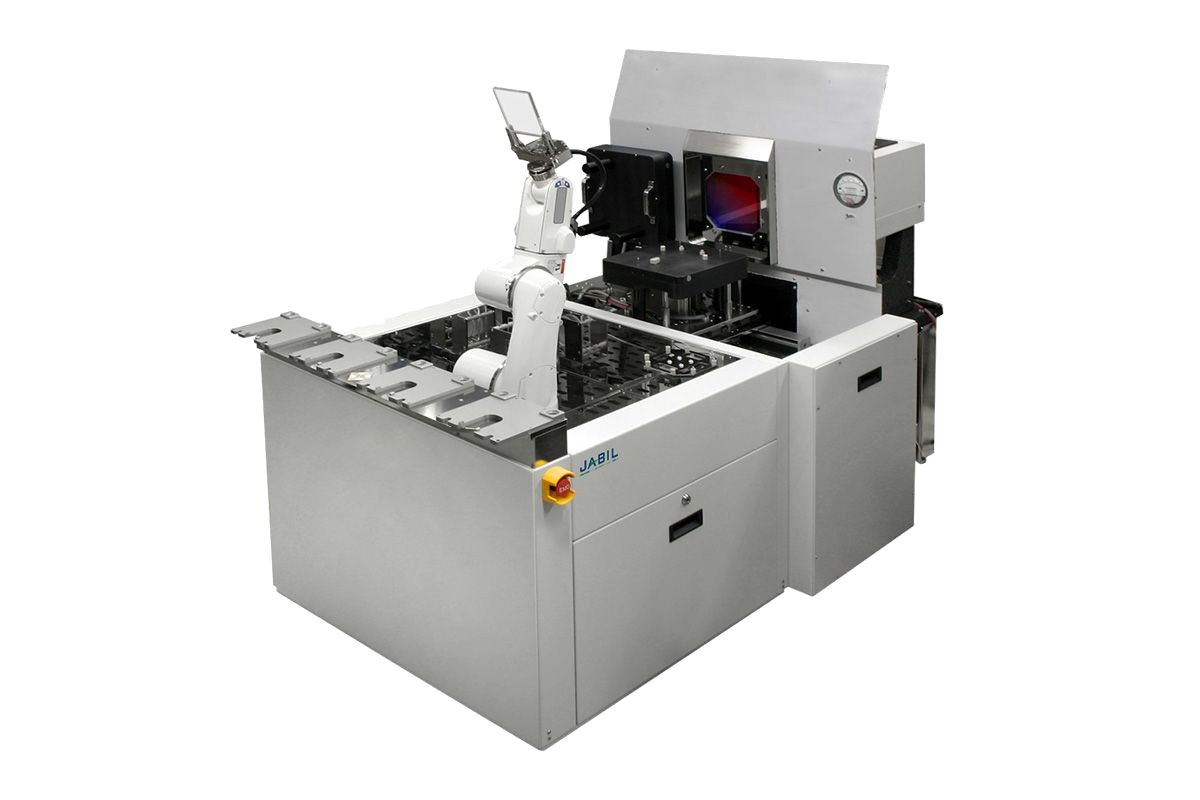

Reticle Handling System

The Reticle Handling System is a highly-reliable mask automation platform, designed to pair up with a variety of process tools or perform inspection, sorting and cleaning applications. Designed to comply with the highest of ISO Class-1 cleanliness standards. The integrated 6-axis robot and edge grip end effector can perform flip and reorientation of reticles from a variety of presentation methods: SMIF POD, Open Cassette, Acclimation Cassette, Blank Box and Compact Box.

-next-gen-mask-handling.png)

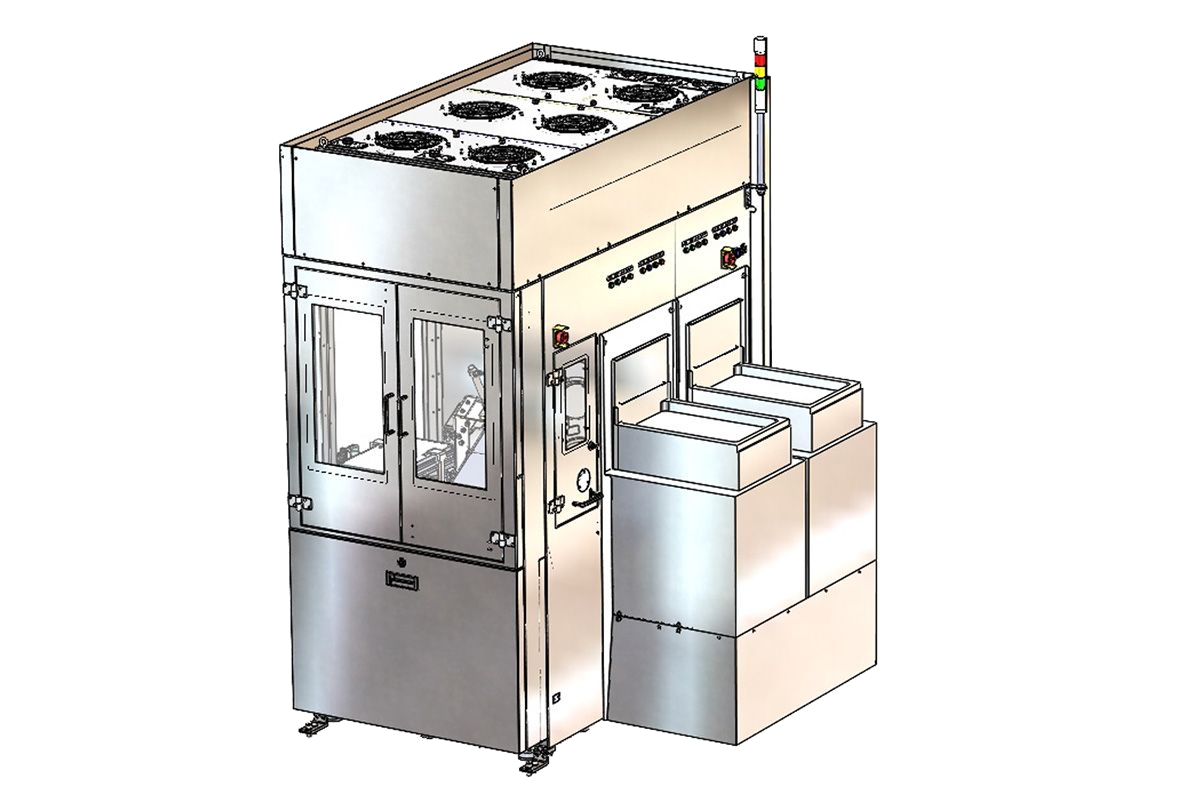

Large Format (6”x12”) Next-Gen Mask Handling

As the industry transitions from the current 6”x6” masks to the larger format 6”x12”, Jabil is leading the development of next-generation automated reticle handling systems. Engineered for the demands of large format EUV and advanced lithography, our automation solutions deliver unmatched precision, reliability, and throughput — enabling a seamless transition to the future of semiconductor manufacturing.

Supported Processes

Semiconductor manufacturers are often faced with the challenging task of finding new, more efficient ways to automate the handling of their wafers. Wafers come in a range of shapes and sizes, thus needing different handling requirements. This is where Jabil can help — whether it’s by solving a complex wafer handling application or integrating automation into your current process tool, our proven experience and deep understanding of wafer handling automation and factory integration requirements allows us to develop wafer handling equipment that addresses all your project needs.

|

System & Technology Options

|

Supported Wafer Types

|

How can Jabil solve your precision automation challenges?

Get in touch with one of our automation experts.