In business lore, some of the most compelling origin stories begin in basements, garages, or dorm rooms. These humble spaces embody accessibility, possibility, and the belief that anyone, anywhere, can build a company that over time grows beyond even their boldest ambitions.

For Jabil, the place was a small kitchen table in suburban Detroit. The year was 1966, when Bill Morean asked James Golden to join him at that table, along with a soldering iron (or two) and a contract to repair circuit boards for one of the country’s leading computer manufacturers. James and Bill welded their first names together to form the company’s name. Sixty years later, that bond is still holding strong.

What Does Jabil Do Today?

Chances are, you have used at least one Jabil-made product today. Digital payment processing terminals. Smart appliances throughout your home. Fitness trackers. A medical device for monitoring glucose or an auto-injector to administer medication. It’s also possible cameras in your car helped you drive safely, or an autonomous robot moved a package through a warehouse en route to your door, or a data center powered the app you just opened to ask a question.

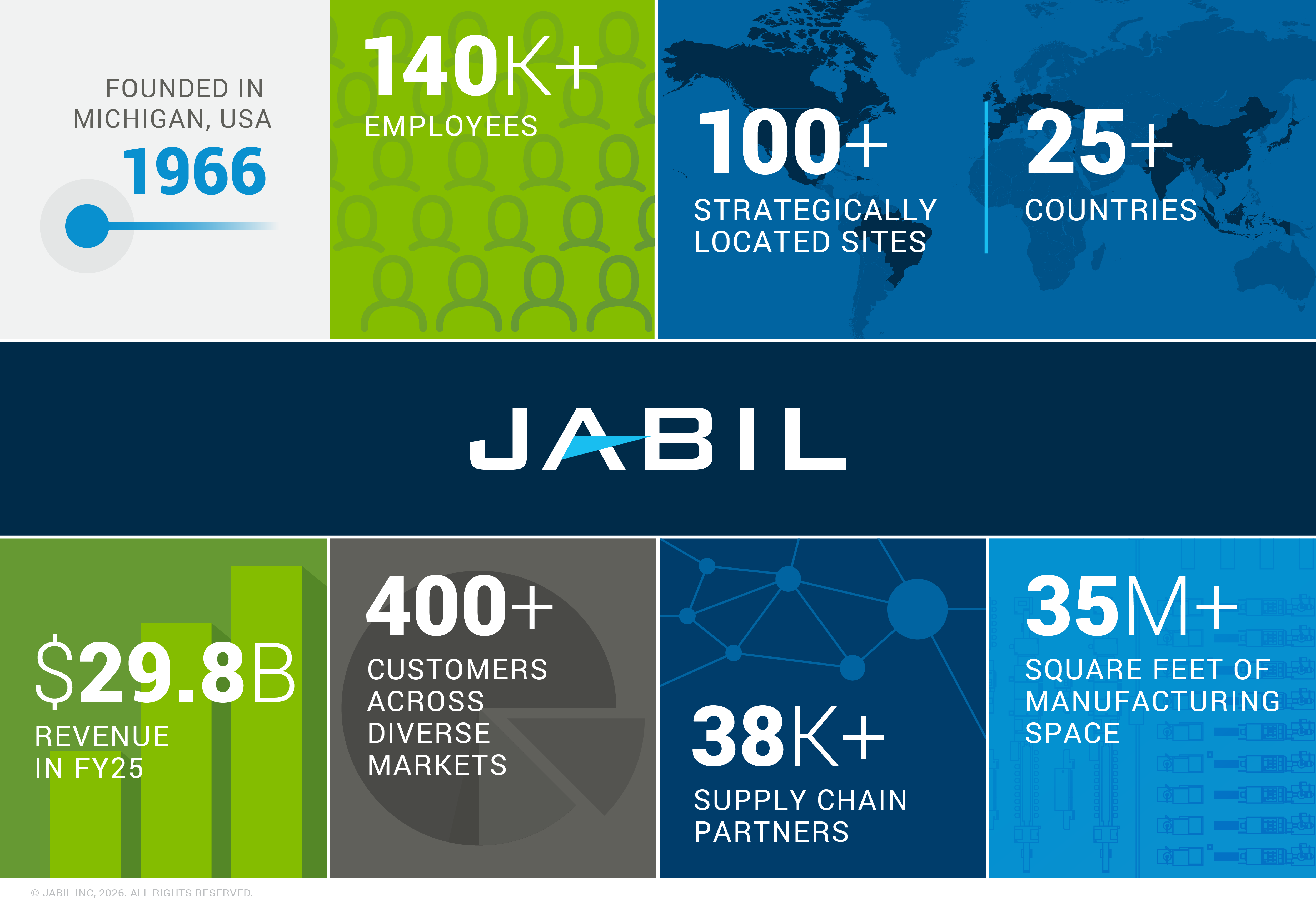

Across almost every industry and sector of the global economy, Jabil teams design, engineer, and manufacture the products that define modern life for more than 400 of the world’s most important brands. Jabil also manages complex global supply chains for those companies every day, including 38,000 global suppliers and more than $25 billion in annual procurement spend. But numbers only tell part of the story.

Looking back over the trajectory of Jabil’s 60-year history, it’s natural to wonder how a single contract, fulfilled by two men at a kitchen table, grew to an organization of 140,000+ employees and 100 global sites — but the more interesting questions focus on what guided this expansion. And why?

The answer is twofold: Jabil built the company it is today by delivering what their customers asked for — what they wanted — while simultaneously evolving to be what they needed.

Jabil’s Transformation Into a Global Manufacturing Solutions Partner

Industry and financial press have, over the years, used shorthand to describe companies like Jabil: electronics subcontractor, contract manufacturer, contract manufacturing organization (CMO).

While contract manufacturing remains core to what Jabil does, the company’s role today is now inclusive of a far richer set of services and solutions, largely due to the changing nature of customer needs. Product portfolios have become more technologically complex while customers’ markets increasingly competitive. Maintaining and growing market share within innovation-driven industries requires navigating multiple workstreams with exceptional agility, cost efficiency, and global scale.

To help customers meet these needs, Jabil has grown with and beyond the traditional contract manufacturing model. The evolution has been shaped along both horizontal and vertical dimensions.

Geographically, Jabil expanded its reach from a regional electronics repair and PCB manufacturing shop to a global network spanning the Americas, Europe, and Asia. Strategically, Jabil has moved toward vertical integration, adding capabilities beyond foundational assembly and manufacturing to include product design, engineering, supply chain management, post-production services, and more to deliver a full set of solutions across the product lifecycle.

The result? Jabil can still build to your prints if that's what you need. But increasingly, customers need a deeper partnership, one that offers expertise and guidance addressing challenges both upstream and downstream from the factory floor.

For Jabil customers, the company’s growth into a manufacturing partner capable of orchestrating all the complex systems, technologies, and logistics required to turn customer ideas into products at global scale meant a fundamental shift in responsibility. Instead of committing their own capital, talent, and attention to managing these interdependent challenges, customers could rely on Jabil to carry that operational burden — allowing them to stay focused on innovation, market growth, and their end customers.

How Six Decades of Technological Change Reshaped Manufacturing

To understand the full scope of what Jabil does today, it helps to look at how the global manufacturing environment itself has changed over time. Technical sophistication across product domains has changed in astonishing ways since the mid-1960s.

The evolution of information technology from the mainframe era through the personal computing revolution; the rise of mobile devices, the internet, and the cloud; the explosion of connected everything; and now the massive AI-fueled data center buildout illustrate how dramatically the tech landscape has transformed. While printed circuit boards (PCBs) are embedded into almost everything these days, so too are sensors, optics technologies, communications protocols, and mobile power management solutions.

Certainly, product architecture has become more complex. But so too has the confluence of factors that original equipment manufacturers (OEMs) must navigate to get products built — from fragile global supply chains and geopolitical shifts to growing sustainability expectations.

The traditional model — where the OEM designs a product, locks the specs, and hands it off to a contract manufacturer — still works well for many brands. But as complexity and risk have increased, many customers found they needed more, particularly when confronted with major supply line disruptions, like those resulting from the COVID-19 pandemic and geopolitics.

A more comprehensive and responsive partnership, like the manufacturing solutions orchestrator model, helps protect OEMs against the disruptive unknown inherent in modern manufacturing, while enabling a more agile and efficient way to manage product portfolios.

For Jabil's customers, this partnership means having 10,000 engineers across disciplines like optics, thermal management, and materials science helping design for manufacturability from day one. It means proactive management of 38,000 suppliers running thousands of AI-powered scenarios daily to spot supply chain risks before they impact delivery. And it means the ability to shift or identically replicate production lines across regions — from Asia to the Americas to Europe — based on tariffs, cost structures, or speed-to-market requirements, supported by a manufacturing footprint built for continuity.

These capabilities didn't appear overnight. They are the result of six decades of incremental strategic decisions, each one expanding not just what Jabil could make, but what they could enable for their customers.

Jabil’s Global Manufacturing Footprint, Built One Step at a Time

Jabil’s first major stride out of the starting blocks came in 1979, securing a $15 million high-volume PCB manufacturing contract with General Motors — transformative for a company whose own revenues had been under $50,000 just years earlier.

By 1982, Jabil relocated headquarters to St. Petersburg, Florida, to support IBM’s personal computer business, doubling sales to $100 million within a year. The company’s narrative had shifted from regional PCB producer to a trusted partner capable of scaling precision electronics manufacturing for complex OEM needs.

When Jabil went public in 1993, international expansion was already underway with a facility in Scotland focused on European electronics customers, followed soon after by key manufacturing sites in Penang, Malaysia, and Guadalajara, Mexico. Customer-focused solutions, delivered on a global scale, were now a defining feature of Jabil’s growing value proposition.

But the moves that most clearly reveal Jabil's customer-focused development strategy have come through the targeted acquisitions and partnerships that have filled in critical layers of the solutions stack to meet the needs of a changing world.

Strategic Manufacturing Investments Built for What’s Next

For Jabil’s leaders, being vigilant to the trends and technologies impacting their customers is job number one. It’s in a sense an inventory of opportunities and challenges and a means for managing the continuous improvement of the partnership. The process determines where customer needs are heading, enabling Jabil teams to plot out a proactive strategy to deliver on what’s next.

Over the last several decades, this discipline has led Jabil to execute a series of targeted investments. Some acquisitions brought deep expertise in specific technologies, such as advanced optics, precision plastic injection molding, silicon photonics, liquid cooling, and power and energy management solutions. Others expanded services within regulated markets like medical device sterilization as well as CDMO services to better serve pharmaceutical customers.

The pattern across these investments is consistent: identify where manufacturing work processes are becoming more complex, invest in capabilities to help solve that complexity, then integrate those solutions and deploy them across Jabil’s global operations platform. Bringing these capabilities together under one roof helps customers reduce complexity, accelerate time-to-market, and mitigate the risk of managing multiple partners.

While Jabil's growth has been shaped by a belief in what's possible, it has also been backstopped by disciplined choices about where to invest resources. The willingness to exit markets has been as strategic as the drive to enter them in the first place.

For example, the 2023 divestiture of Jabil’s mobility business freed capital and resources for emerging opportunities in healthcare and for the rapid buildout of AI and data center infrastructure in North America, providing greater diversification at both a sector level and geographically.

How Jabil’s Cross‑Industry Diversification Creates Customer Value

Jabil’s diversification strengthens the value of its vertically integrated model. Capabilities developed to solve complex challenges in one market often apply directly to others, as many modern products — whether in healthcare, mobility, industrial automation, or data center infrastructure — share common manufacturing demands.

Sensors, optics, and embedded computing increasingly sit at the core of these products, driving similar requirements around miniaturization, precision, reliability, and quality at scale. Because Jabil has built and integrated these capabilities across its global footprint, customers don’t have to source them piece by piece.

That ability to apply proven solutions across industries is one of the less visible but most powerful advantages of Jabil’s manufacturing model.

Yet, managing all of these capabilities and solutions has itself become more complex. How does the modern manufacturing solutions orchestrator manage its own operations? For Jabil, scaled, standardized processes are central to how their factories operate with AI, automation, and advanced analytics, transforming traditional factory floors into exceptionally efficient, adaptive environments.

The Digital Factory: AI‑Driven Manufacturing Already in Operation

The digital transformation of manufacturing has been discussed for years, often framed as a future state. At Jabil, it’s already operational.

AI, automation, and advanced analytics are turning traditional factory floors into intelligent, adaptive environments where physical and digital systems work in concert. When an issue appears on one production line — a quality variation, a process inefficiency, a potential defect — the system flags it automatically, and more importantly, ensures these vital insights are distributed across Jabil’s global network. Robotics handle repetitive or high-risk tasks, enabling employees to do more creative, higher value work. AI-powered optical inspection tools catch defects the unassisted human eye might miss. Predictive maintenance prevents equipment failures before they cause downtime. The result: higher yields, faster throughput, fewer defects, and a safer work environment.

The same digital intelligence extends beyond factory walls into supply chain management. Jabil’s platforms use AI and digital twins to monitor the flow of materials, capacity, and risk across the entire supplier network. These systems run thousands of "what-if" scenarios daily: What if a component gets delayed in Thailand? What if a customer needs to shift production regions? The platform models the options, calculates the tradeoffs, and provides customers with data-driven choices, often before they know a problem is coming.

For OEMs, the impact is tangible: faster time-to-market, more accurate demand forecasting, and flexible fulfillment models. But perhaps most importantly, it frees customers from the burden of maintaining cutting-edge manufacturing infrastructure themselves. Capital and talent that might have gone toward production can be dedicated to designing the next product, entering new markets, and staying ahead of competition.

Back at that Kitchen Table

For James and Bill, their initial circuit board piecework wasn't glamorous. It didn't hint in the slightest at the scope of what their partnership would someday deliver. It was just work. Careful, meticulous, get-it-right work. Two sets of hands at a table, soldering components that would eventually disappear into larger machines that would, in turn, provide the value of harnessed technology to companies around the world. Theirs was a service enabling someone else's breakthrough. Nearly 60 years later, that dynamic hasn't really changed at all.

What has changed is the scale. Today, Jabil is the quiet partner behind more than 400 of the most respected and innovative brands on the planet — the brand behind the brand. Jabil’s name rarely appears on a bezel, a package, or a product launch stage. And that's by design.

The world's innovators lead, empowered by a Jabil partnership that helps bring their ideas to life reliably and repeatedly at a pace and scale few companies can match.

How can Jabil make your product a reality? Contact us.

No matter how complex or demanding the project, we’re helping today’s innovators solve it. Get started with a trusted partner.